Busbar Assembly Line: The Heartbeat of Modern Manufacturing Efficiency

In the wave of modern manufacturing, Busbar (busbar) assembly lines have become an indispensable part of many industries with their efficient, precise and reliable performance. The Busbar assembly line is not only the highway of the power distribution system, but also a key link in realizing industrial automation and intelligent production.

Busbar assembly line is an automated production line specially used for the production and assembly of busbars. Busbar, as an important component in the power system that connects various power sources and loads, bears the important task of efficient transmission of electric energy. The Busbar assembly line uses highly automated equipment and precise processes to accurately assemble busbars and other components to form a stable and reliable power transmission system.

Busbar assembly lines offer significant advantages over traditional wiring methods. It is easy to design, has low impedance and strong anti-interference ability, while saving space and making assembly simple and fast. These characteristics make Busbar assembly lines popular in rapidly developing industries such as new energy vehicles, wind power, and photovoltaics.

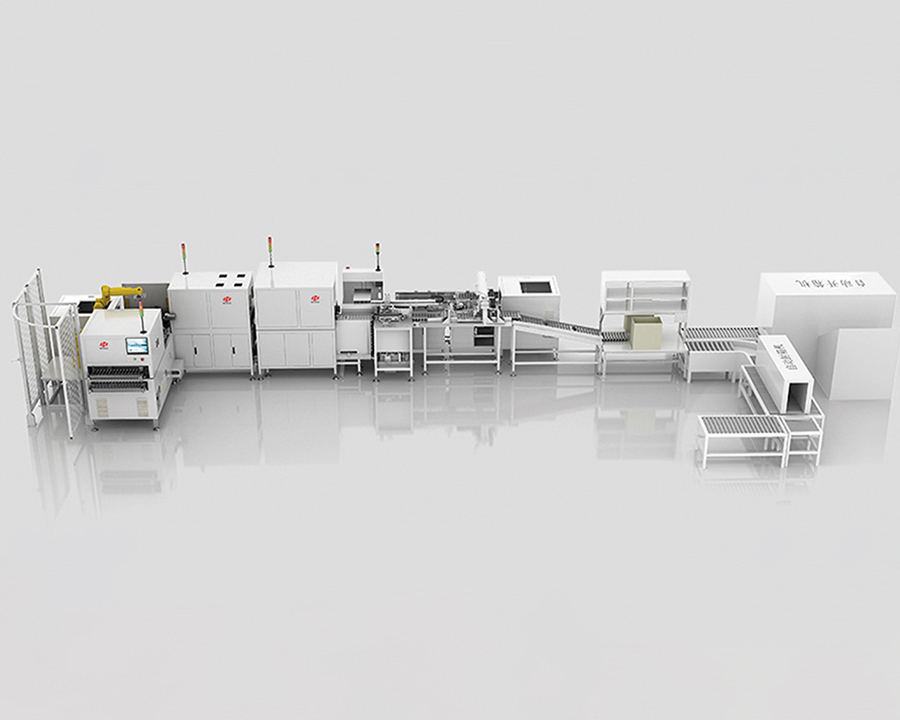

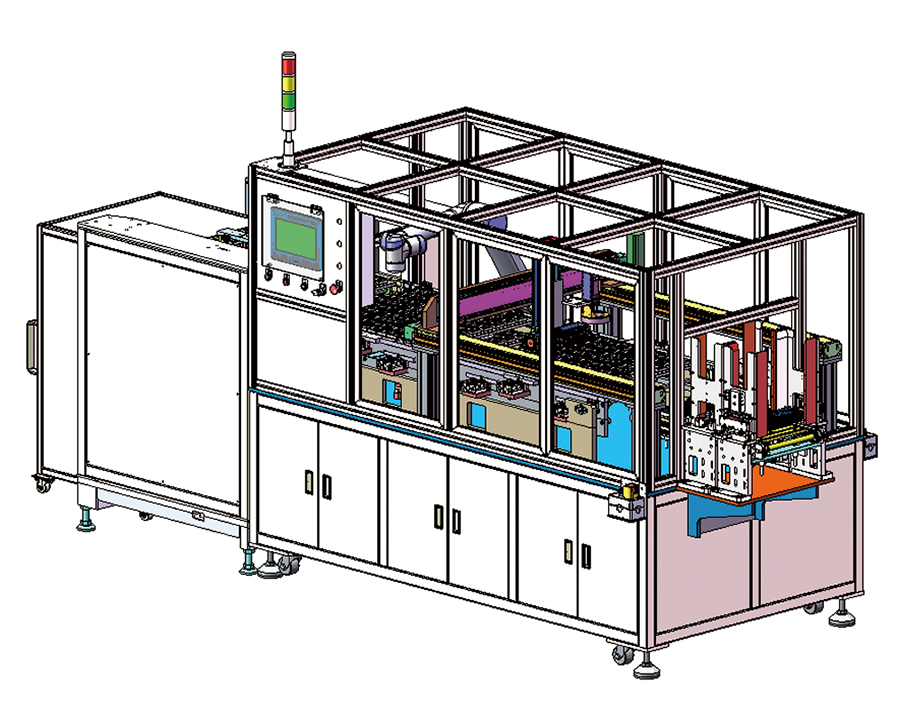

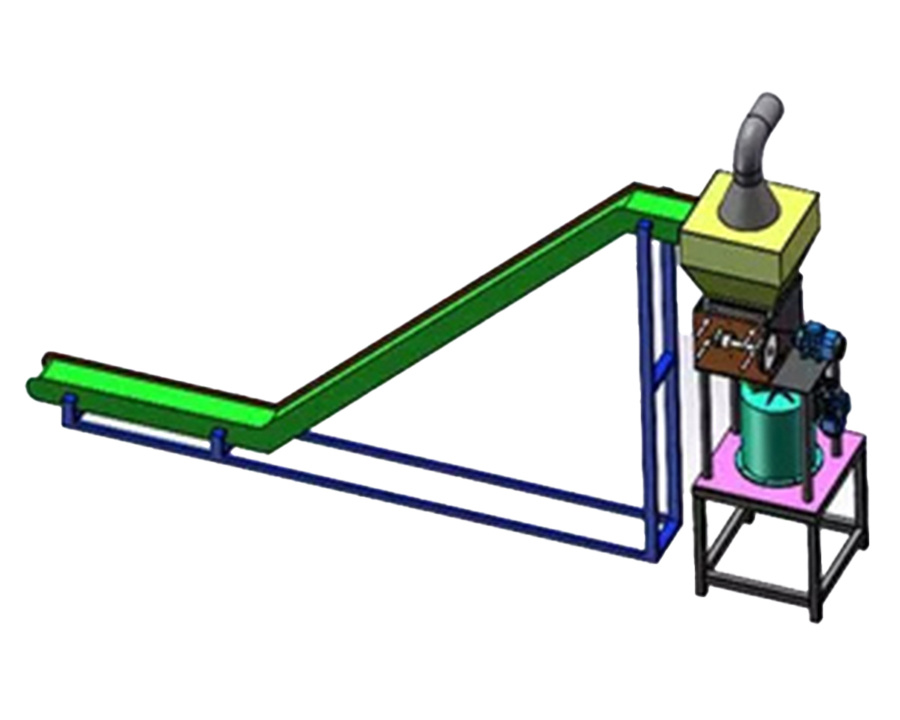

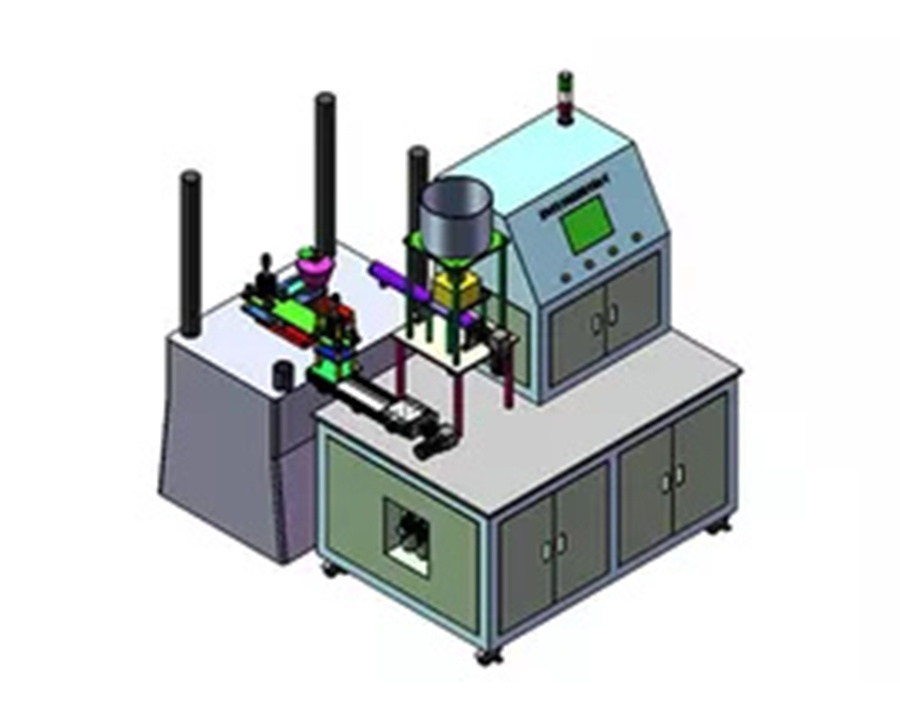

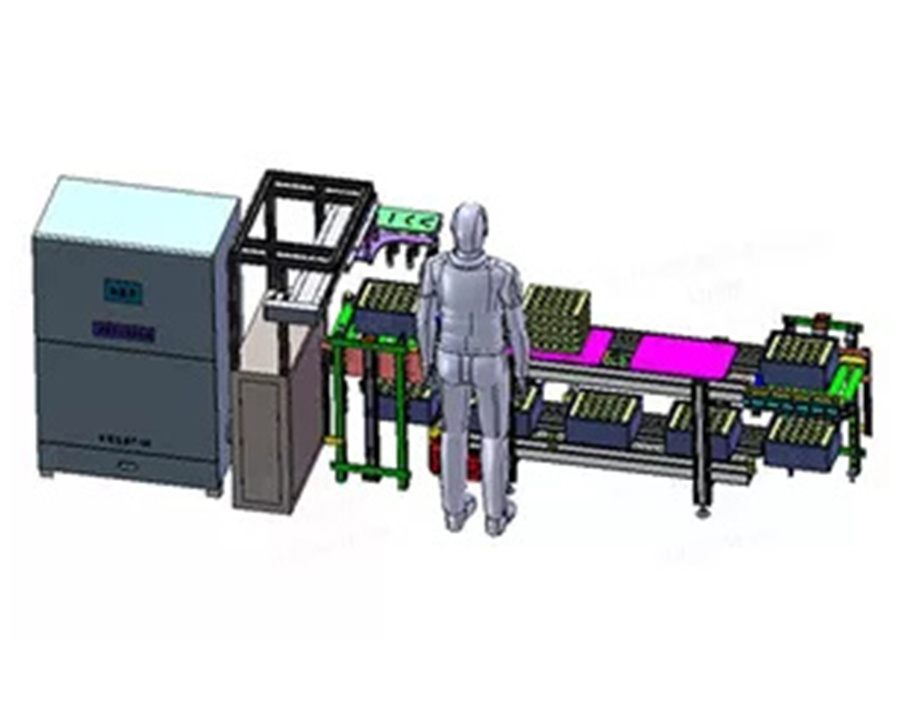

The process flow of the Busbar assembly line usually includes stator core loading, winding, paint peeling, rounding, laser marking, comprehensive performance testing and material collection. These processes are realized through highly automated equipment, which greatly improves production efficiency and product quality.

In terms of technological innovation, the Busbar assembly line adopts an advanced industrial control data collection system to achieve traceability of product production process information. At the same time, the accuracy and reliability of the busbars are ensured through advanced technologies such as laser welding, precision measurement and automated assembly. Some advanced Busbar assembly lines also integrate intelligent detection methods such as visual inspection, material reverse detection, and missing assembly identification, further improving the intelligence level of the production line.

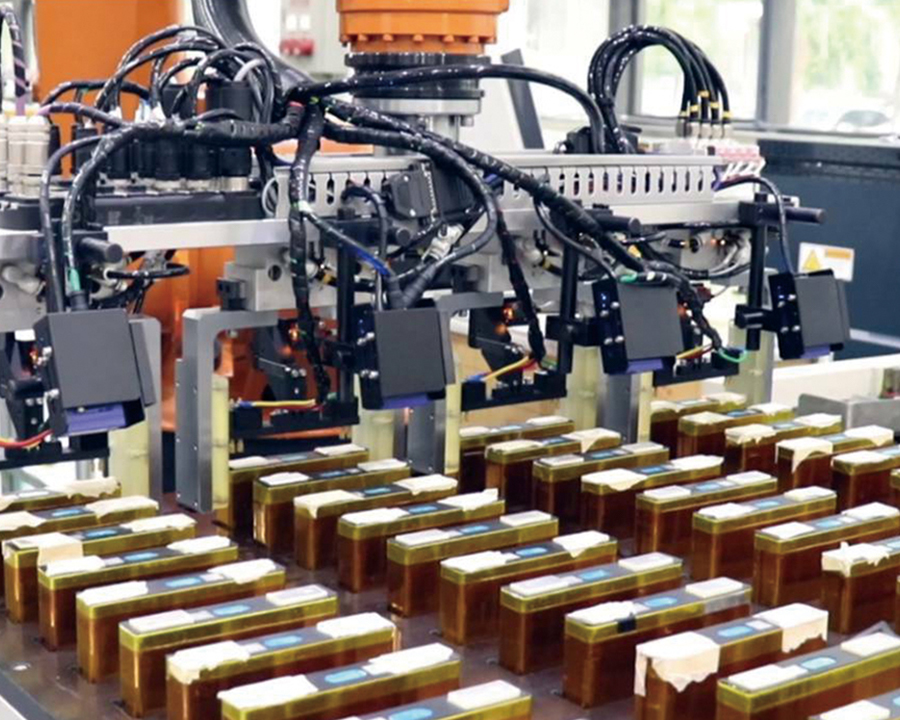

Busbar assembly lines are widely and deeply used in manufacturing. In the field of new energy vehicles, the Busbar assembly line is used to produce busbars in battery modules to ensure efficient transmission and safety of electric energy in the battery system. In the wind power and photovoltaic industries, Busbar assembly lines are used to produce busbars in key equipment such as inverters and combiner boxes, providing strong support for grid-connected power generation of renewable energy.

With the transformation, upgrading and intelligent development of the manufacturing industry, the Busbar assembly line will also usher in broader development prospects. On the one hand, with the continuous emergence of new materials and new processes, the performance and reliability of the Busbar assembly line will be further improved. On the other hand, with the widespread application of technologies such as the Internet of Things and big data, the Busbar assembly line will achieve more intelligent and networked production and management.

In the future, Busbar assembly lines will pay more attention to the development of energy conservation, environmental protection, efficient intelligence and customized production. Through technological innovation and industrial upgrading, the Busbar assembly line will contribute more to the high-quality development of the manufacturing industry.

English

English русский

русский عربى

عربى