Busbar assembly line: the invisible artery of power transmission

In the field of power transmission and distribution, busbar assembly line is not only the core component of key facilities such as substations and data centers, but also the invisible artery that promotes the development of new energy and intelligent manufacturing. With the continuous advancement of technology and the transformation and upgrading of industrial structure, busbar assembly line is leading the power industry to move towards a more efficient, environmentally friendly and intelligent direction with its unique advantages.

As the "highway" of power transmission, busbar is the key conductor connecting large electrical equipment such as transformers, mutual inductors, inlet and outlet lines and various electrical devices. In the substation, the busbar builds an efficient and stable power transmission network through complex and sophisticated assembly lines. These busbars include the main busbar and equipment connection line of the primary equipment part, the AC busbar of the station power part, the DC busbar of the DC system, and the small busbar of the secondary part, which together constitute a solid foundation for power transmission and distribution.

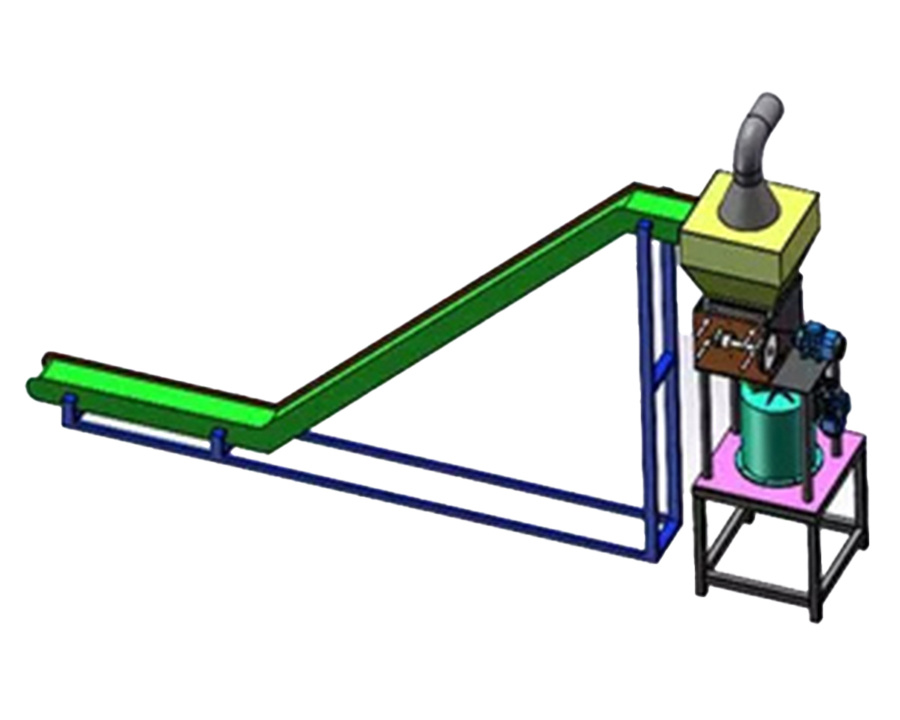

The busbar assembly line is the key link in the construction of this foundation. It not only requires high accuracy and stability, but also needs to adapt to the special needs of different application scenarios. From the selection of materials (such as copper, aluminum, steel, etc.) to the optimization of processing technology, and then to the refined management of the assembly process, each link is directly related to the overall performance and reliability of the busbar system.

In recent years, with the vigorous development of the new energy industry, the busbar assembly line has also ushered in a climax of technological innovation. On the one hand, in order to meet the needs of emerging fields such as new energy vehicles, smart grids, and photovoltaic equipment for efficient and environmentally friendly power transmission technology, the busbar assembly line has begun to develop in the direction of lightweight, high conductivity, and easy installation. As an important power transmission technology, soft busbar has been widely used in charging piles, distribution cabinets, and power replacement equipment due to its advantages of high transmission efficiency, safety and stability, and small footprint.

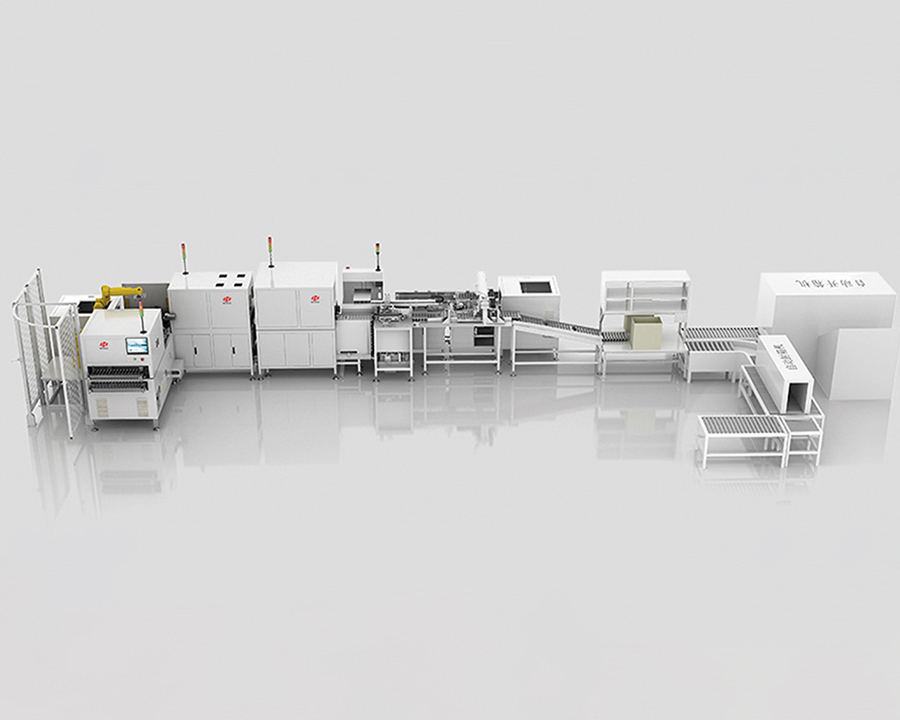

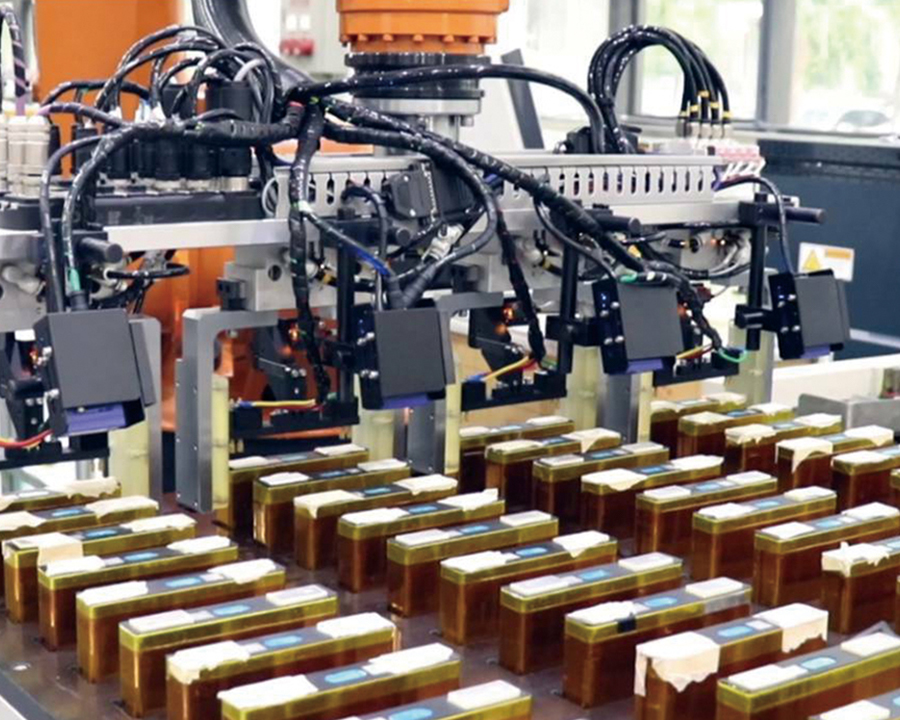

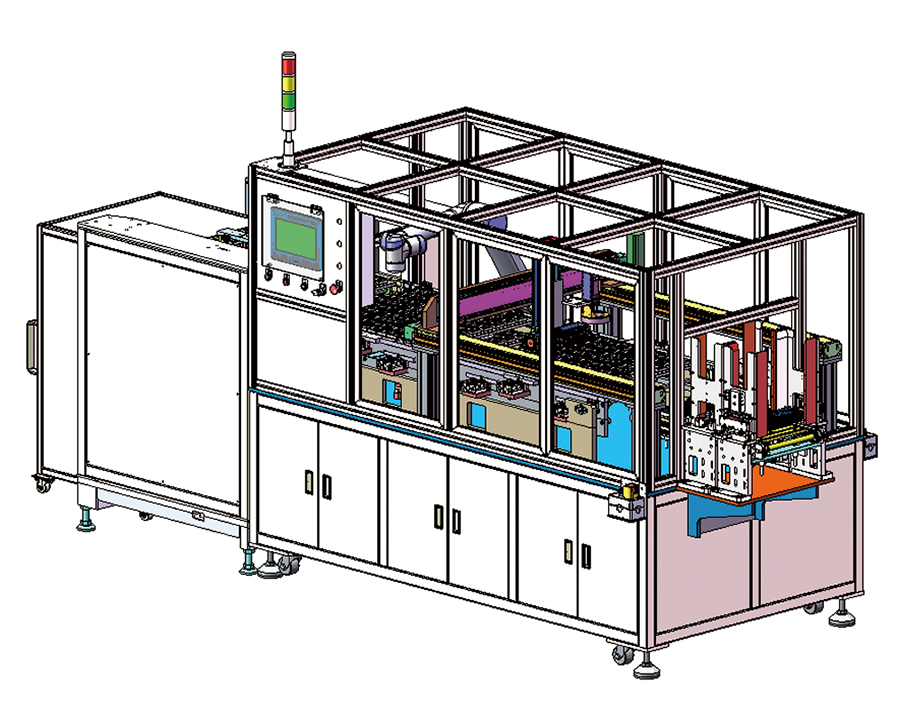

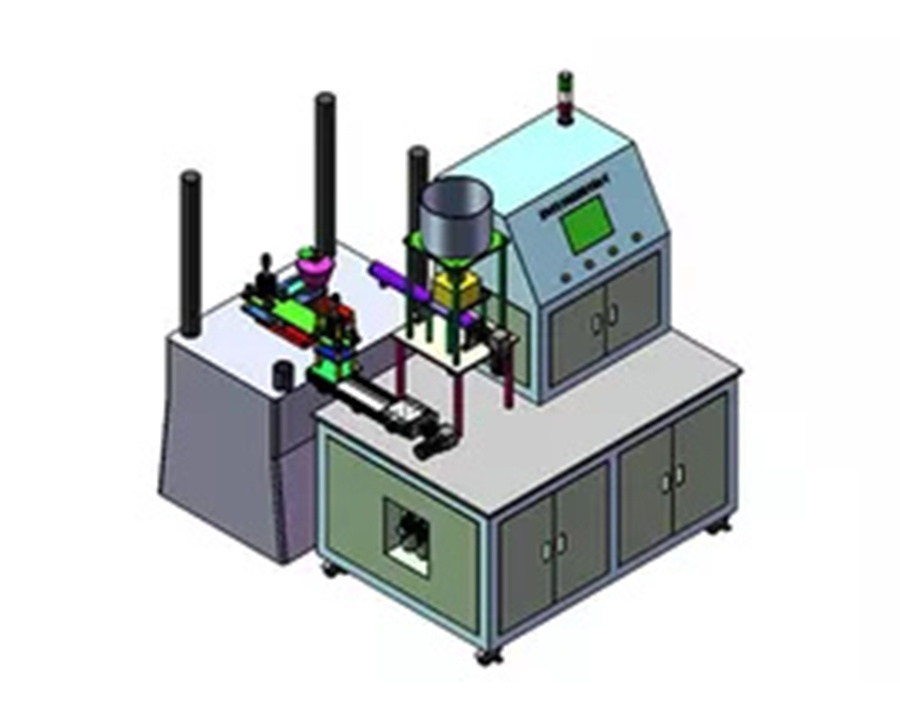

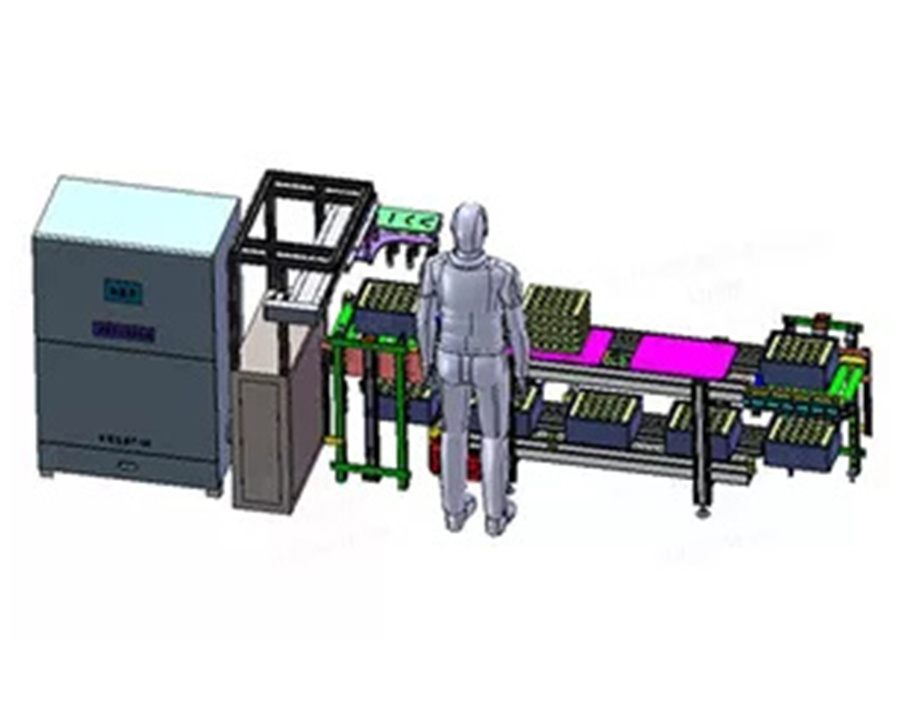

On the other hand, the introduction of intelligent and automated technologies has significantly improved the production efficiency and quality level of busbar assembly lines. By introducing advanced robots, automated equipment, and intelligent control systems, the busbar assembly line can achieve functions such as precise positioning, automatic welding, and intelligent detection, which greatly improves production efficiency and product quality. At the same time, the application of intelligent technology also enables the busbar assembly line to better adapt to complex and changing production environments, and improves production flexibility and reliability.

As an important part of the field of power transmission and distribution, busbar assembly line is promoting the rapid development of new energy and intelligent manufacturing industries with its unique advantages. With the continuous advancement of technology and the continuous optimization of industrial structure, busbar assembly line will continue to usher in new development opportunities and challenges. We have reason to believe that in the future development, busbar assembly line will continue to play its important role and contribute to the sustainable development of the power industry and even the entire society.

English

English русский

русский عربى

عربى