Innovation of automatic motor assembly production line: How will automation and intelligence reshape the future of manufacturing?

In today's rapidly developing science and technology, as the core component of industrial equipment, the level of automation and intelligence in the production process of motors is directly related to the competitiveness of the entire manufacturing industry. The innovative technology of the motor automatic assembly production line is the key driving force that has emerged in this context. It not only reshapes the production method of motors, but also leads the manufacturing industry to a more efficient, more precise and more intelligent direction.

The traditional motor assembly production line is highly dependent on manual operation, which is not only inefficient, but also difficult to ensure the consistency and accuracy of assembly. With the continuous integration and innovation of advanced technologies such as automation technology, robotics technology, machine vision and artificial intelligence, the motor automatic assembly production line has achieved a leapfrog development from manual to intelligent.

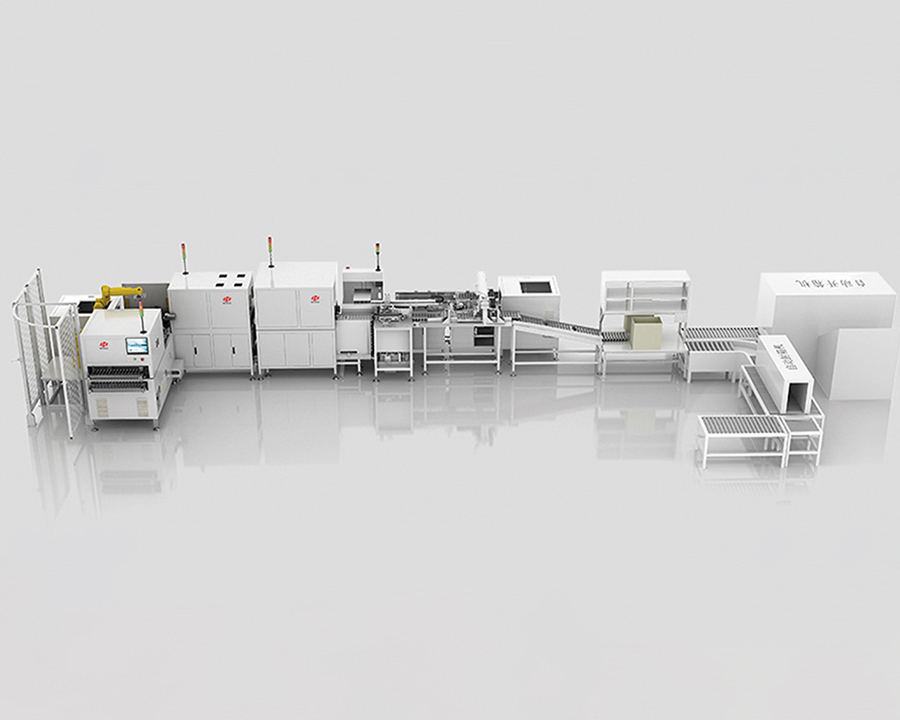

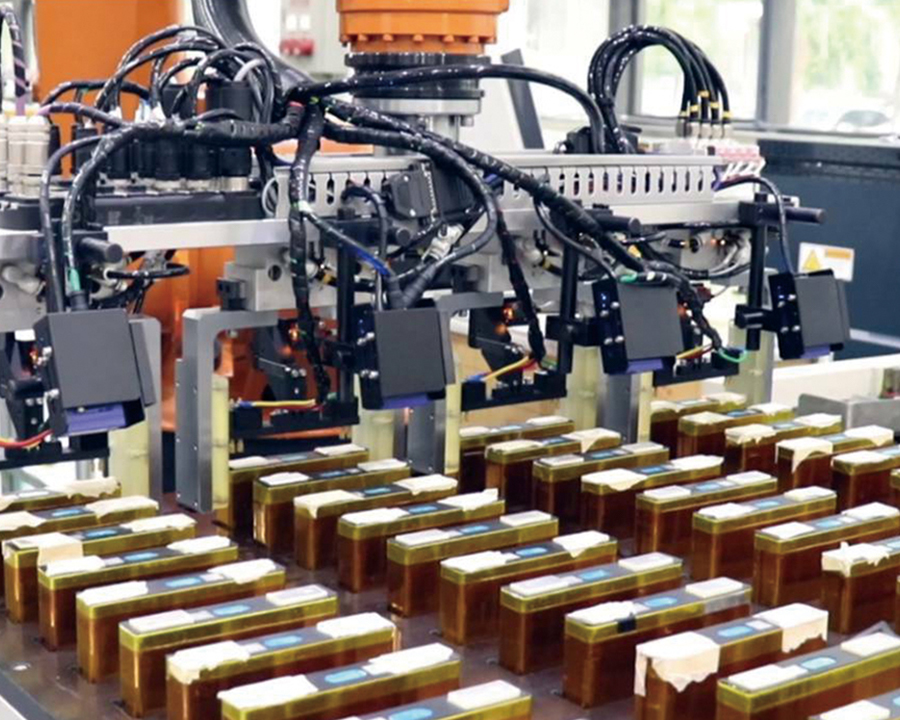

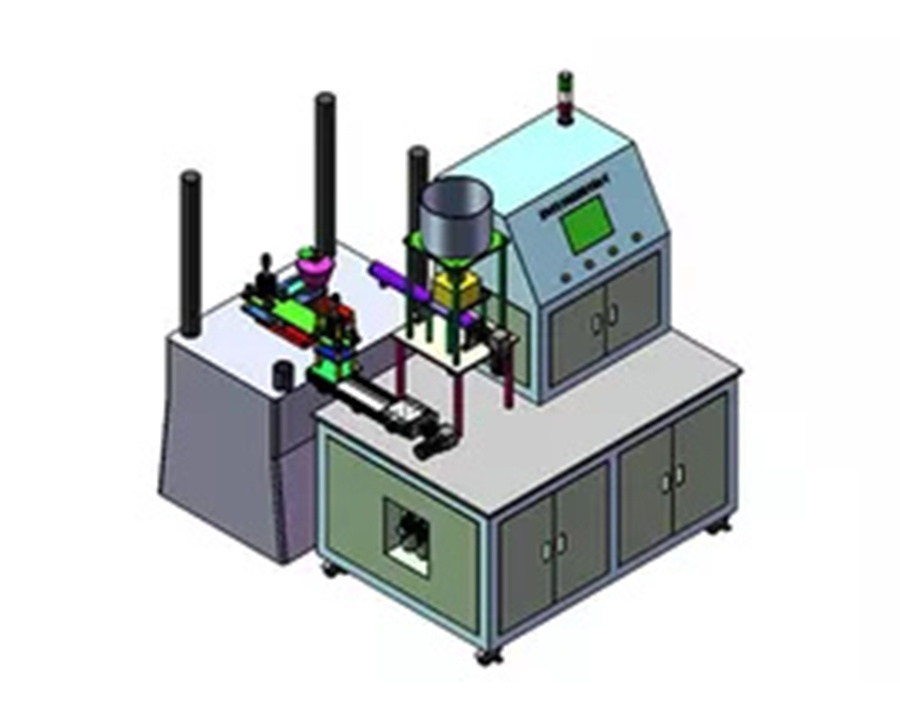

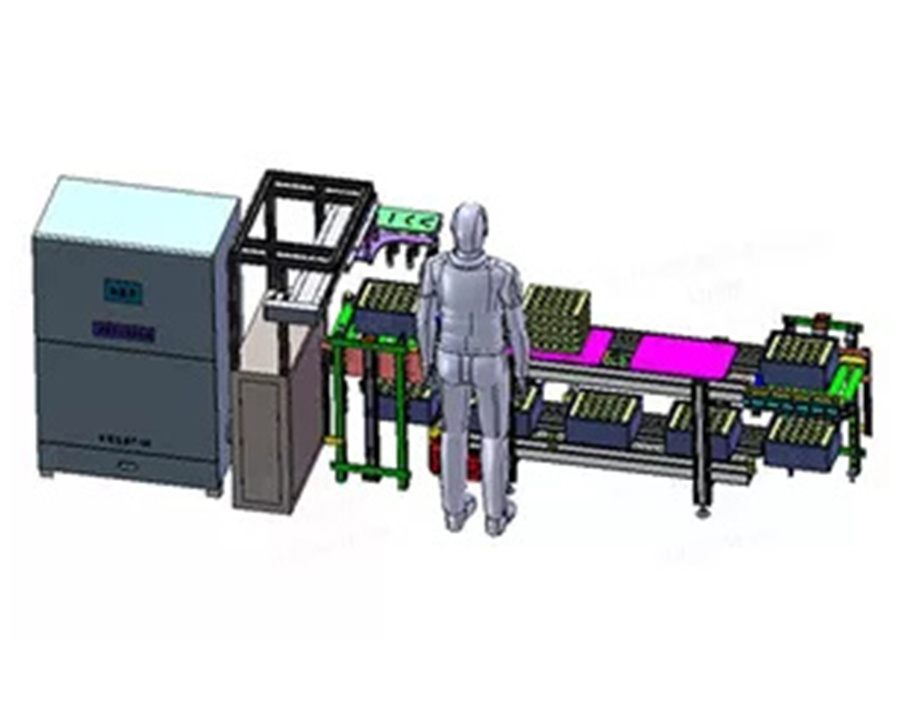

The motor automatic assembly production line integrates high-precision robotic arms, servo motors, intelligent sensors and other precision automation equipment. These devices can accurately complete the grasping, positioning and assembly of parts through precise control systems, realizing a high degree of automation and precision in the assembly process. For example, the robotic arm can accurately assemble the stator and rotor together according to the preset program without manual intervention, greatly improving the efficiency and consistency of assembly.

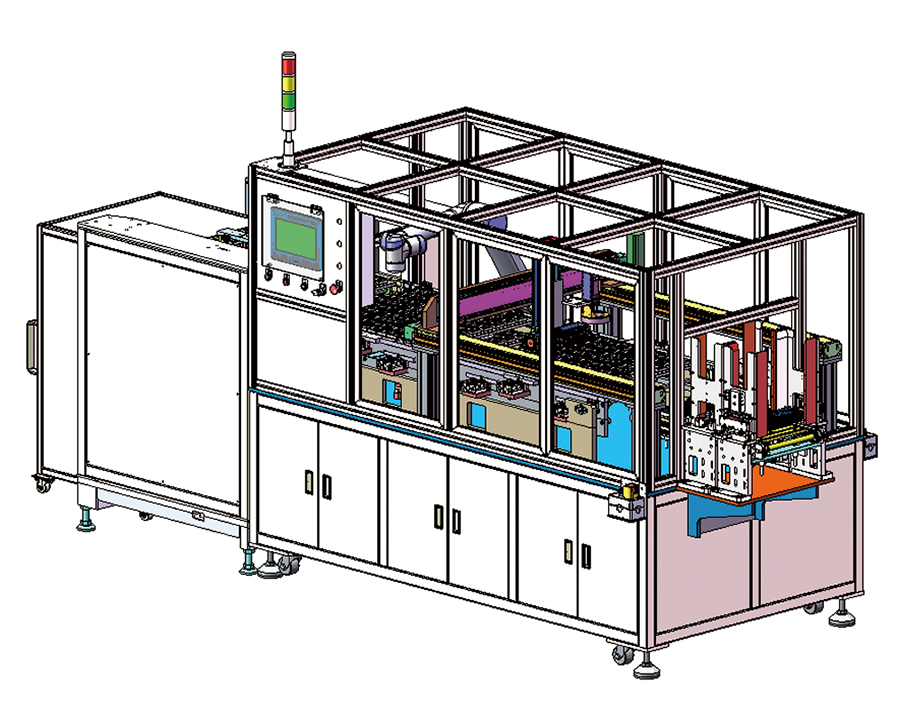

The introduction of machine vision technology has brought revolutionary changes to the motor automatic assembly production line. Through high-definition cameras and advanced image processing algorithms, the production line can monitor and detect key parameters in the assembly process in real time.

The motor automatic assembly production line is also equipped with advanced data acquisition and analysis systems. These systems can collect various data in the production process in real time, including key indicators such as production efficiency, energy consumption, and failure rate. By deeply mining and analyzing these data, companies can accurately identify production bottlenecks, optimize process flows, and even predict equipment maintenance needs. This data-driven production optimization method not only improves the overall efficiency of the production line, but also provides valuable decision-making support for companies.

The continuous operation capacity of the automated production line greatly improves production efficiency and reduces production cycles. Compared with traditional manual assembly methods, the automated assembly production line can complete motor assembly tasks at a higher speed to meet the needs of mass production.

The combination of precision automation equipment and machine vision technology ensures the high accuracy of the motor assembly process. Whether it is the positioning, installation, or tightening torque control of components, micron-level accuracy can be achieved, greatly improving the performance and reliability of the motor.

The application of the data acquisition and analysis system enables the production line to have intelligent management capabilities. Enterprises can monitor production data in real time to discover and solve problems in a timely manner; at the same time, they can also use big data analysis technology to predict production trends and equipment maintenance needs, and realize the refinement and intelligence of production management.

The innovative technology of the motor automatic assembly production line is an important milestone in the intelligent development of the manufacturing industry. It not only improves production efficiency, ensures product quality, and reduces production costs, but also provides strong support for the sustainable development of the manufacturing industry. In the future development, we have reason to believe that the motor automatic assembly production line will continue to lead a new chapter in intelligent manufacturing.

English

English русский

русский عربى

عربى