Automatic Flag-Making Machine: Revolutionizing the Art of National Symbolism

In the realm of manufacturing, automation has revolutionized countless industries, from automotive assembly lines to precision electronics. Yet, one might not immediately think of flag-making as a field ripe for automation. However, the advent of the automatic flag-making machine has transformed this traditional craft into a high-tech endeavor, blending artistry with cutting-edge technology.

Historically, flag-making was a labor-intensive process involving skilled artisans who meticulously sewed together fabric pieces, often by hand. This method, while producing beautiful and intricate designs, was slow and prone to human error. With the rise of industrialization, mechanization began to渗透 into the flag-making industry, but it was not until recent decades that full automation became a reality.

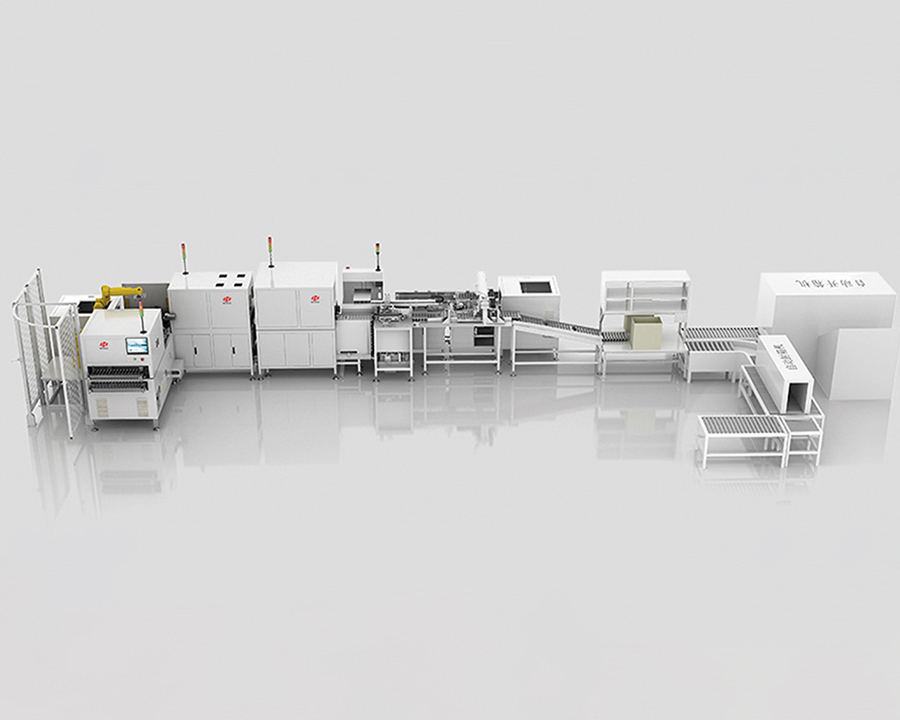

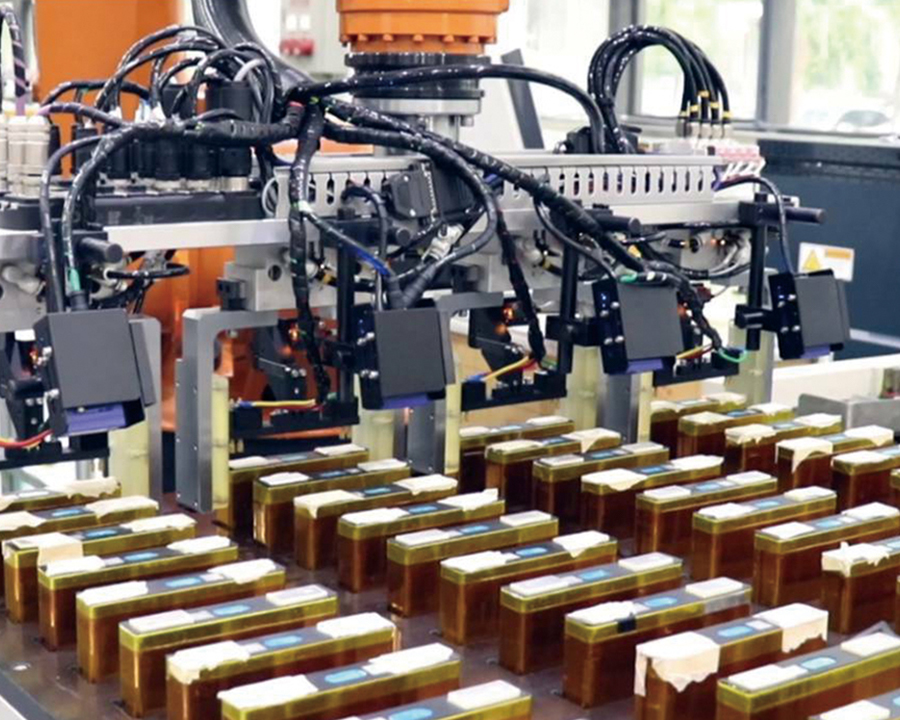

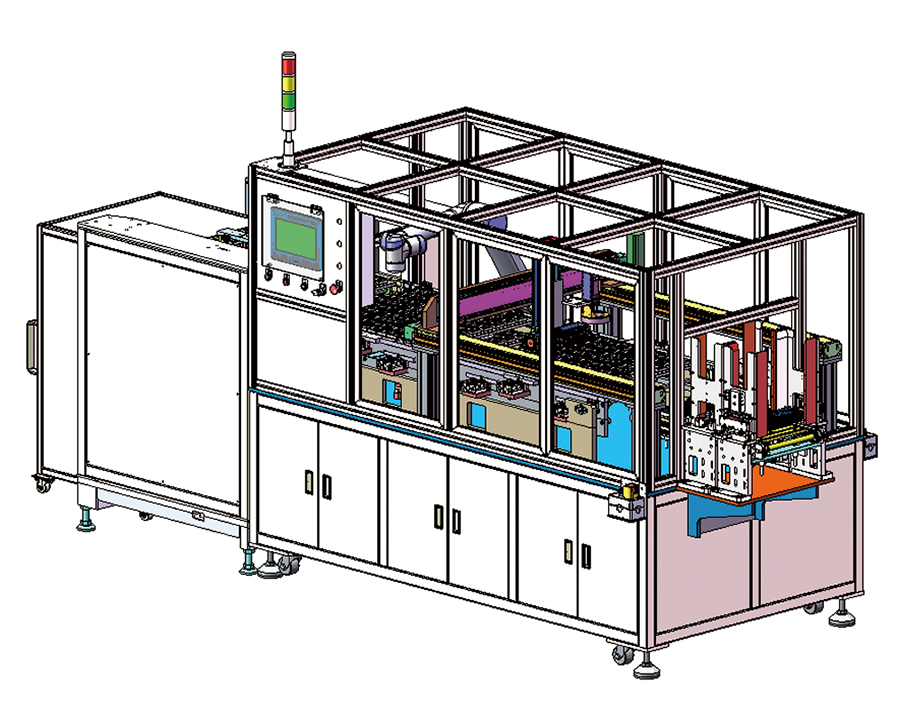

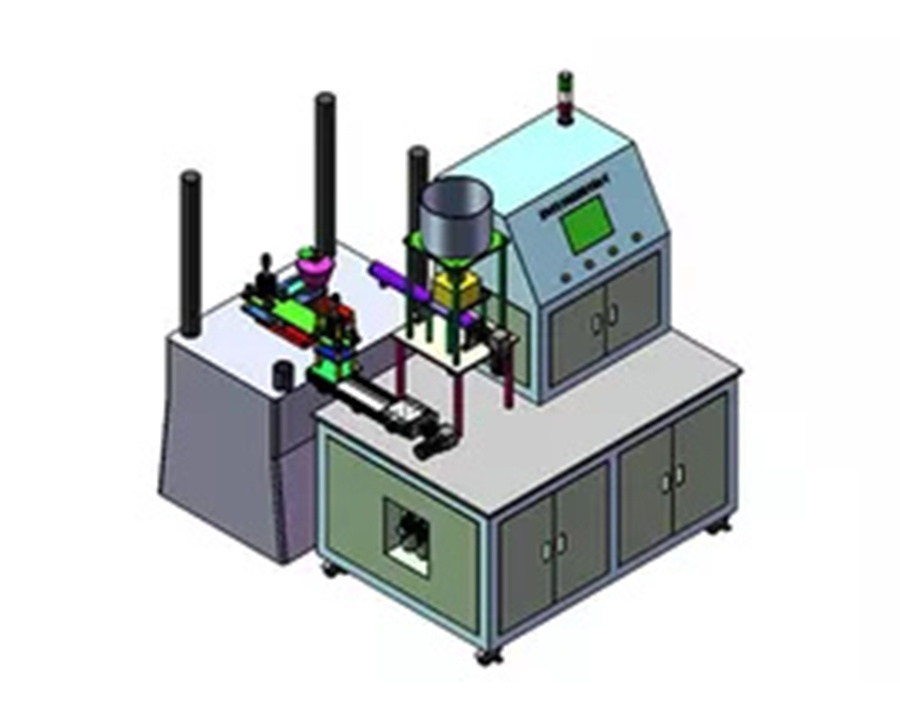

An automatic flag-making machine is a sophisticated piece of equipment that combines robotics, computer programming, and precision machinery. It operates on a principle similar to other automated manufacturing systems, but with unique adaptations to suit the specific requirements of flag production.

At the heart of the machine is a computer system that controls the entire process. This system receives input in the form of design specifications, such as the dimensions of the flag, the colors to be used, and any intricate patterns or symbols that need to be incorporated. From this input, the computer generates a series of instructions that guide the machine through each step of the production process.

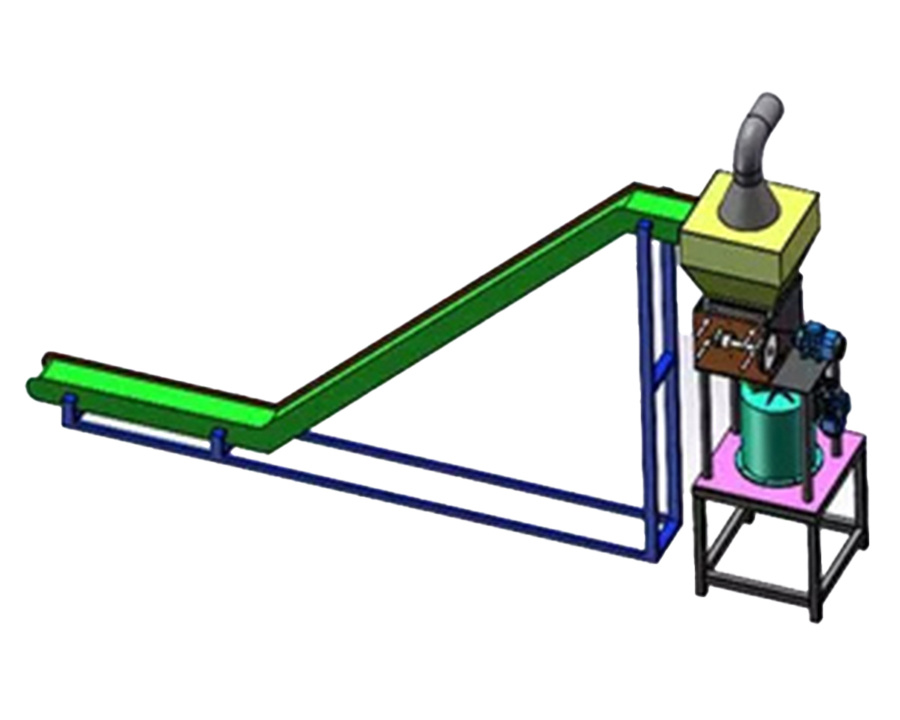

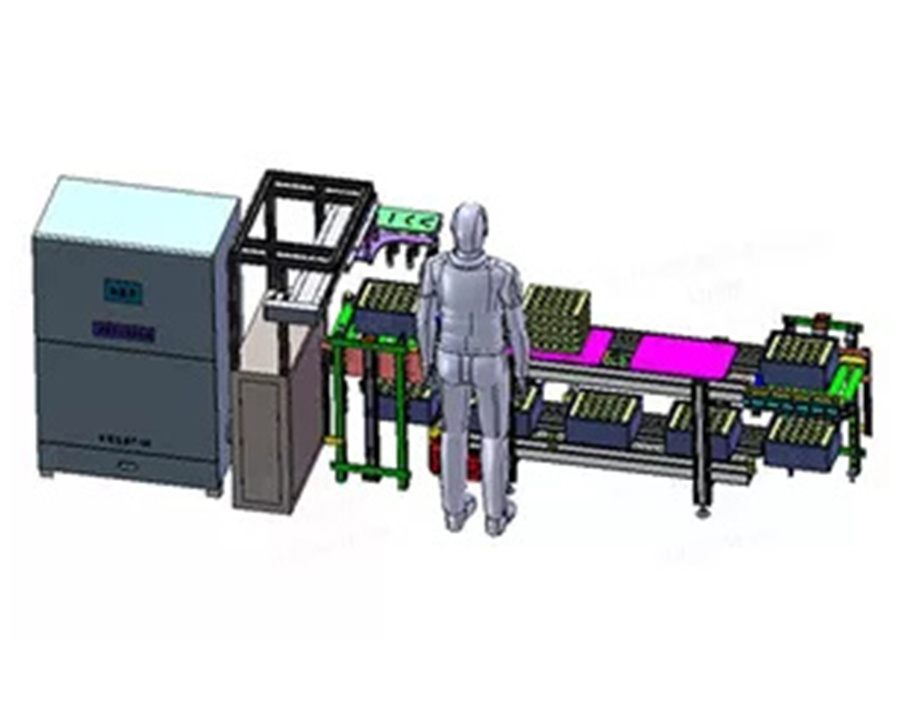

One of the most impressive features of the automatic flag-making machine is its ability to handle a wide variety of materials. Whether it's cotton, nylon, polyester, or even specialized materials like silk, the machine can adapt its settings to ensure optimal cutting, sewing, and finishing. This versatility is crucial in satisfying the diverse needs of customers, who may require flags for different purposes, from ceremonial displays to outdoor use.

Precision is key in flag-making, as even the smallest deviation from the design can alter the flag's appearance and meaning. The automatic flag-making machine achieves this precision through a combination of high-resolution imaging, precision cutting tools, and advanced sewing mechanisms. The machine can cut fabric with millimeter-level accuracy, ensuring that each piece fits perfectly together.

Efficiency is another significant advantage of automation. A single automatic flag-making machine can produce hundreds of flags in a single day, far outpacing the output of even the most skilled artisan. This increased productivity not only reduces costs but also allows for a faster turnaround time, enabling customers to receive their orders more quickly.

In addition to precision and efficiency, the automatic flag-making machine offers unparalleled customization options. With the ability to program the machine with specific design parameters, manufacturers can create unique flags that cater to individual or organizational needs. This level of customization is particularly valuable in a world where branding and identity are increasingly important.

English

English русский

русский عربى

عربى