Future Energy Context: Unveiling Advanced Busbar Assembly Line Technology

In the field of modern industry and energy distribution, busbar assembly lines are not only the core components of power transmission and distribution, but also the key force to promote the development of cutting-edge fields such as smart grids, data centers and electric vehicle charging stations. With the rapid development of science and technology, busbar assembly lines are no longer just a simple splicing of metal conductors, but a comprehensive solution that integrates high-tech materials, precision manufacturing processes and intelligent control systems.

Traditionally, busbar assembly lines are mainly used in large power facilities such as power plants and substations to transmit high-power electrical energy from generators to distribution systems. These busbars are usually made of high-conductivity materials such as copper or aluminum and assembled by bolting or welding to ensure stable transmission of current. However, with the growing demand for clean energy, efficient utilization and intelligent management, the design and production of busbar assembly lines are undergoing unprecedented changes.

Driven by new materials science, busbar assembly lines have begun to use innovative materials such as composite metals, superconducting materials and nano-coatings, which not only significantly improve the conductivity efficiency, but also enhance the corrosion resistance and mechanical strength of the busbar. For example, superconducting busbars can achieve almost lossless power transmission at extremely low temperatures, which is of great significance for reducing energy waste and improving power grid efficiency. The application of nano-coating effectively prevents oxidation and corrosion on the busbar surface, prolongs service life and reduces maintenance costs.

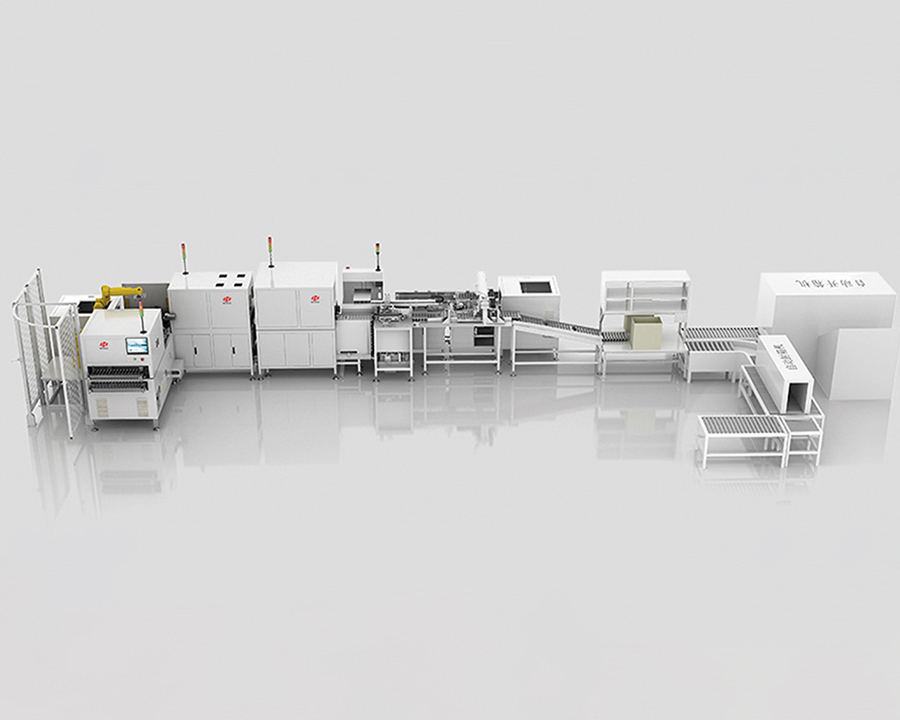

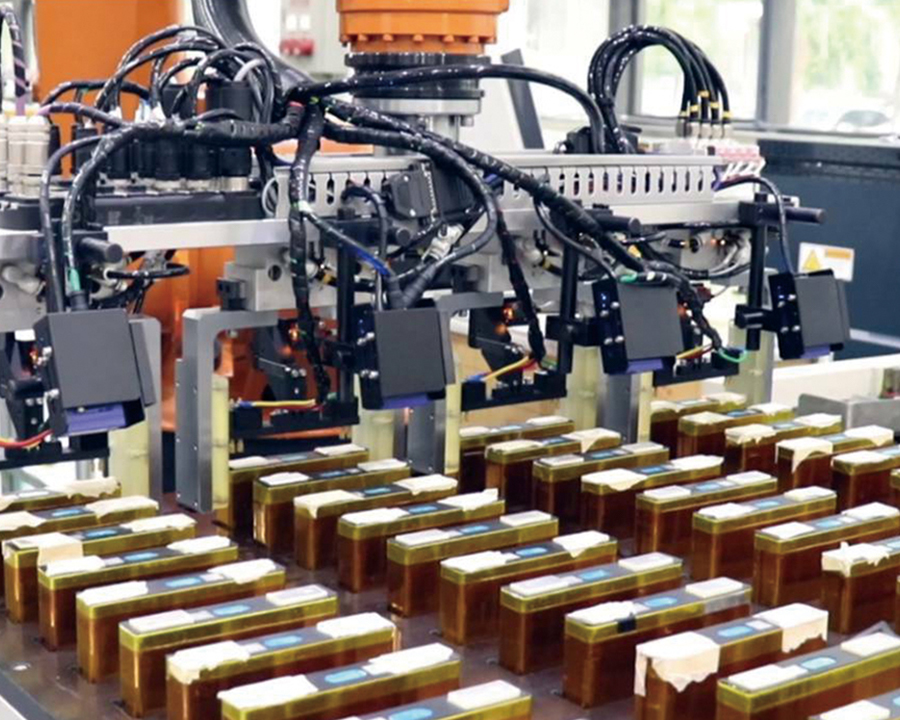

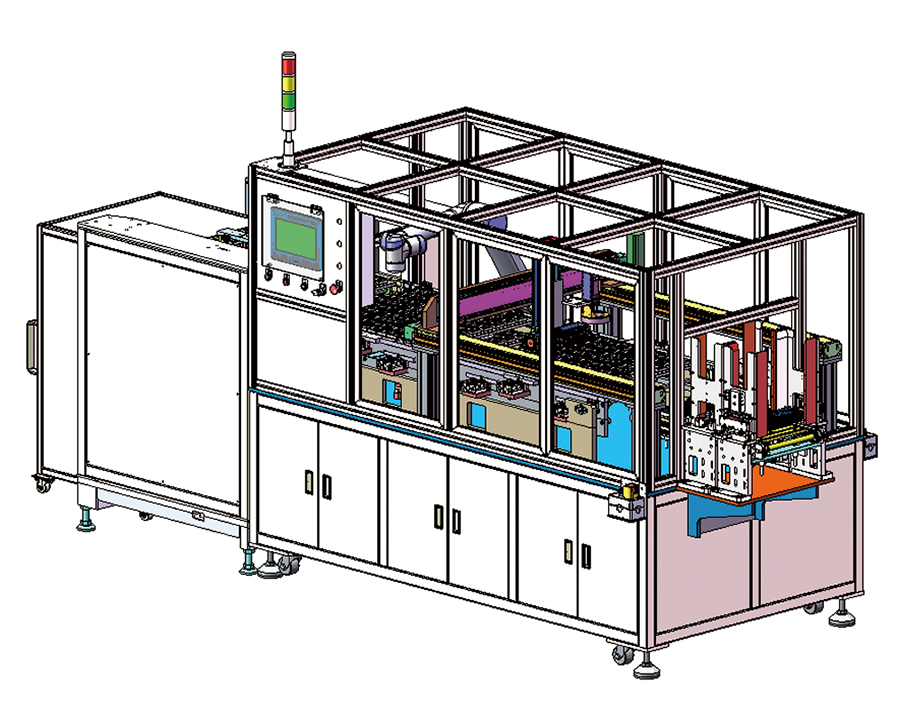

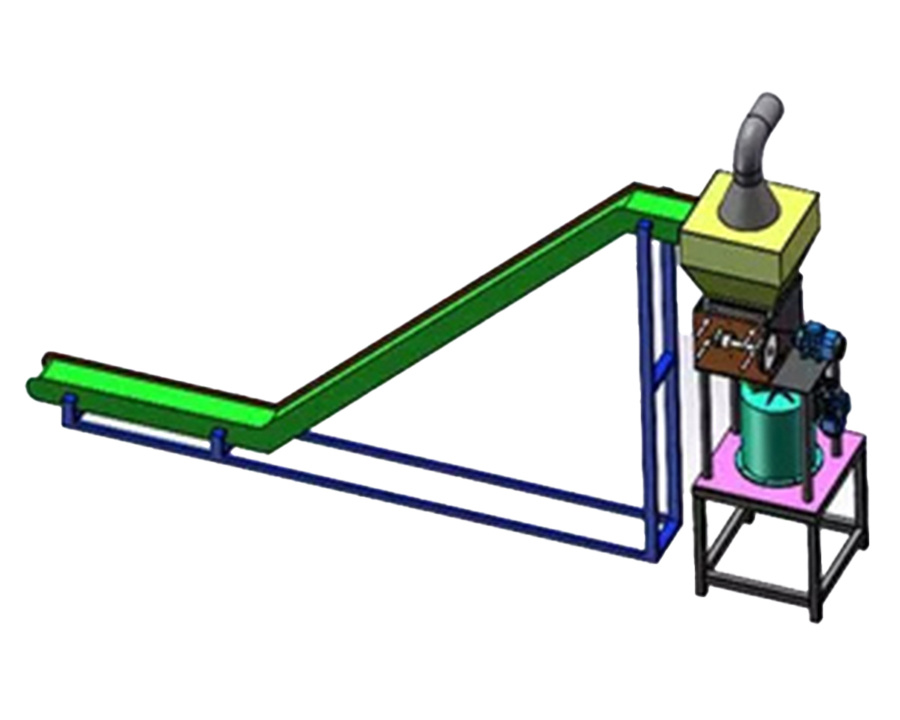

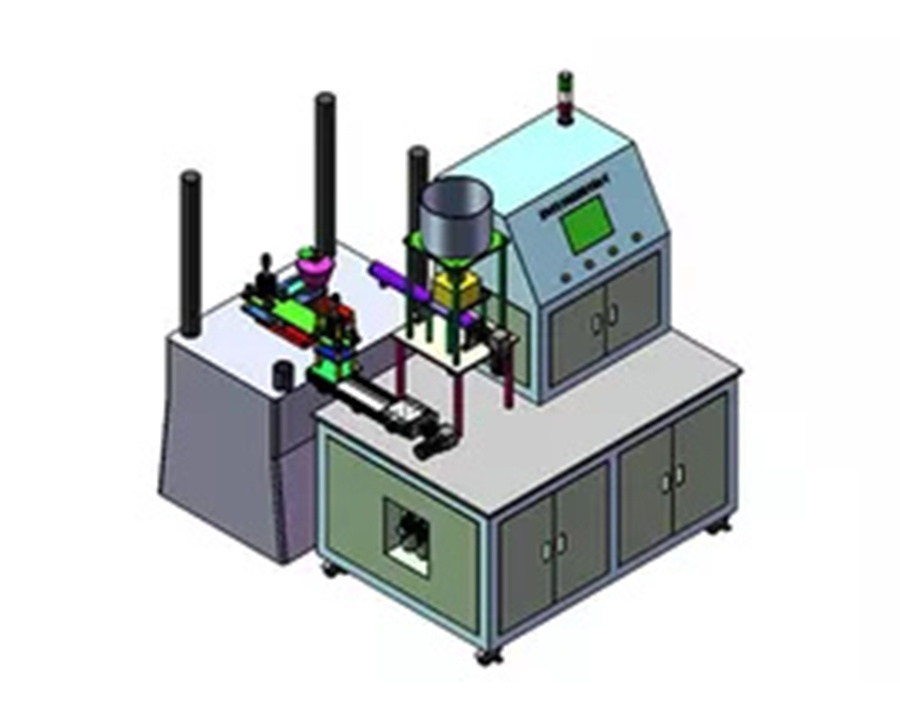

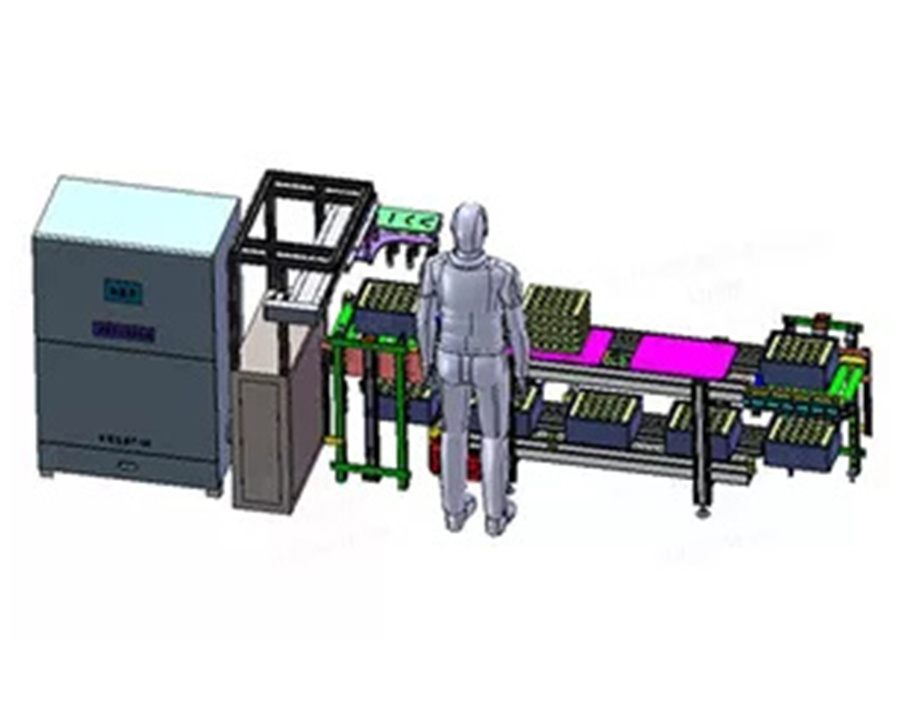

The integration of intelligent and automated technologies has enabled the busbar assembly line to achieve a comprehensive upgrade from design to production. Through 3D modeling and simulation analysis with CAD/CAM software, engineers can accurately calculate busbar dimensions, optimize layout, and ensure optimal efficiency of power transmission. At the same time, the application of automated assembly robots, laser welding systems, and high-precision detection systems makes the busbar assembly process more accurate and efficient, greatly reduces human errors, and improves product quality.

With the support of the Internet of Things and big data technologies, modern busbar assembly lines have the ability of remote monitoring and intelligent diagnosis. Through an integrated sensor network, the working status of the busbar can be monitored in real time, including key parameters such as current, temperature, and vibration. Once an abnormality is found, the early warning mechanism is immediately triggered, which facilitates the operation and maintenance personnel to respond quickly and effectively prevent failures. In addition, the predictive maintenance strategy based on big data analysis can identify potential risks in advance and arrange maintenance plans reasonably, further ensuring the stability and security of power supply.

Facing the challenges of global energy transformation, busbar assembly lines are moving towards a greener, smarter and more sustainable direction. On the one hand, by adopting renewable energy generation and energy storage technology, busbar assembly lines will become an important part of smart grids and promote the widespread application of clean energy; on the other hand, combined with cutting-edge technologies such as artificial intelligence and blockchain, busbar assembly lines will achieve a higher level of automation and transparent management, laying a solid foundation for building a safer, more efficient and flexible energy system.

English

English русский

русский عربى

عربى