Automotive relay assembly and testing equipment: dual drive of technological innovation and quality assurance

In the modern automotive industry, automotive relays, as key components of automotive electronic control systems, play a vital role. They not only control various electrical equipment in the car, such as lights, horns, electric doors and windows, and starter motors, but also directly affect the safety, reliability and comfort of the car.

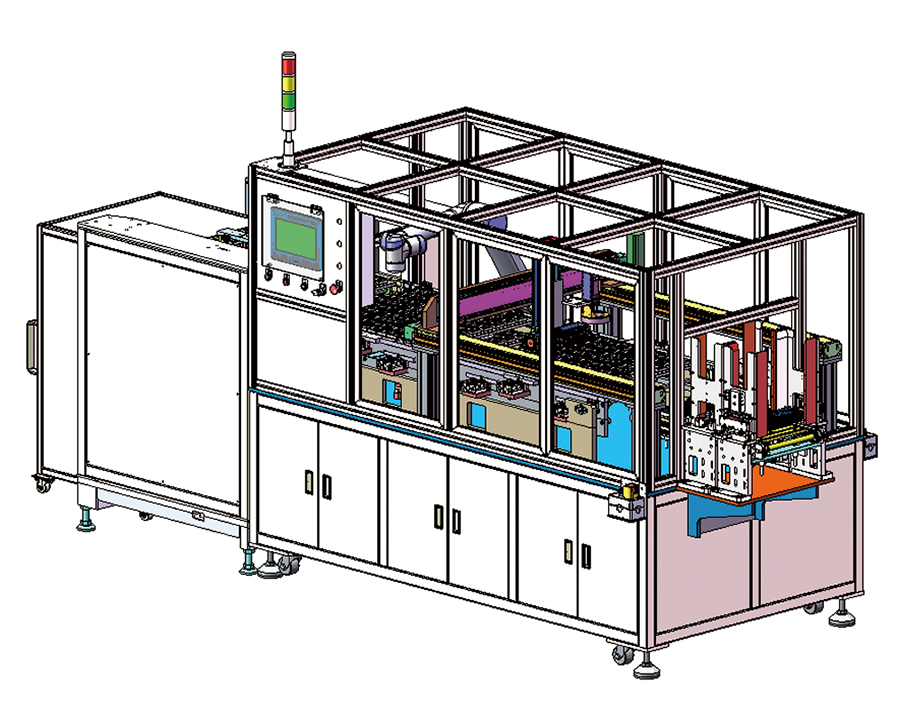

With the rapid development of automotive electronic technology, automotive relay assembly and testing equipment is also evolving. Traditional testing equipment often relies on manual operation, which is inefficient and prone to errors. Modern assembly and testing equipment integrates the design concepts of intelligence and efficiency, and realizes precise control and real-time monitoring of the relay assembly process by introducing advanced sensors, machine vision and automatic control systems.

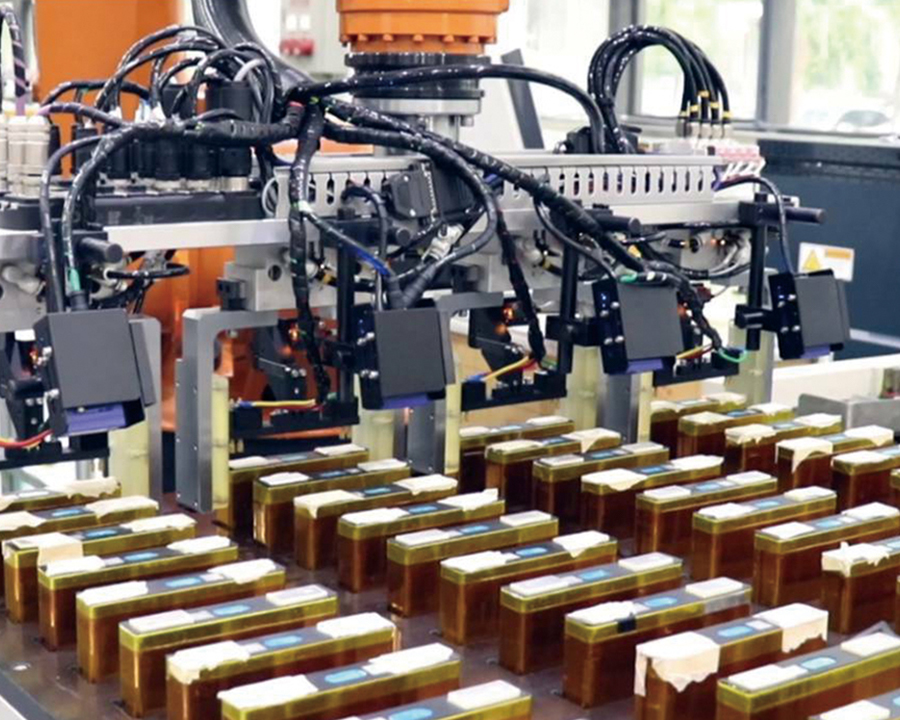

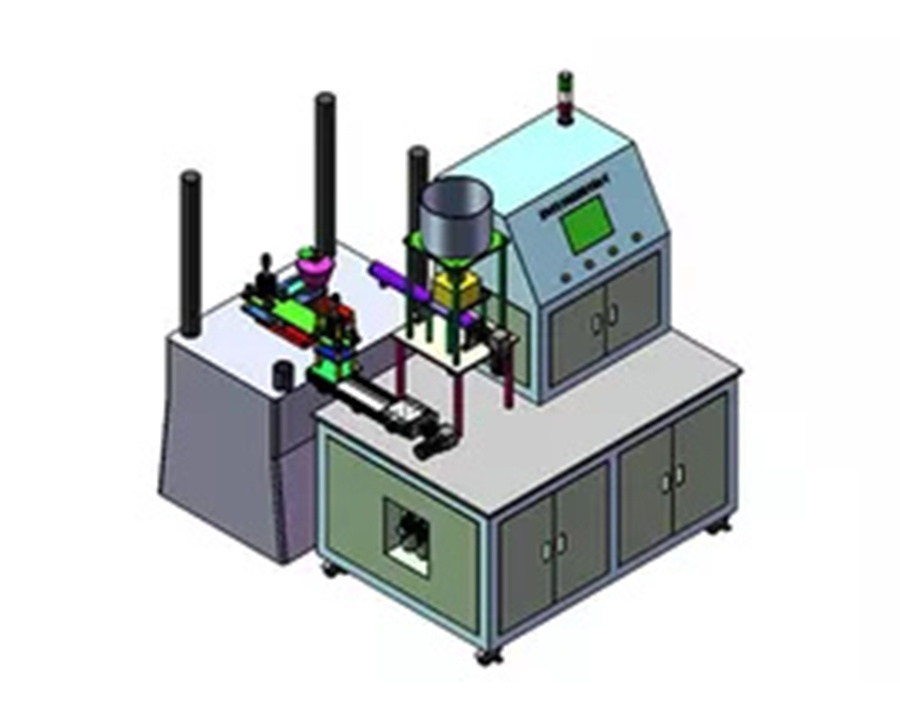

Intelligent assembly and testing equipment can automatically identify the model, specifications and assembly requirements of the relay, and automatically complete the assembly task according to the preset program. This not only improves the assembly efficiency, but also greatly reduces the error rate caused by human factors. At the same time, the application of machine vision technology enables the detection equipment to detect abnormal conditions in the assembly process in real time, such as part dislocation, poor assembly, etc., so as to issue alarms in time and take corresponding corrective measures.

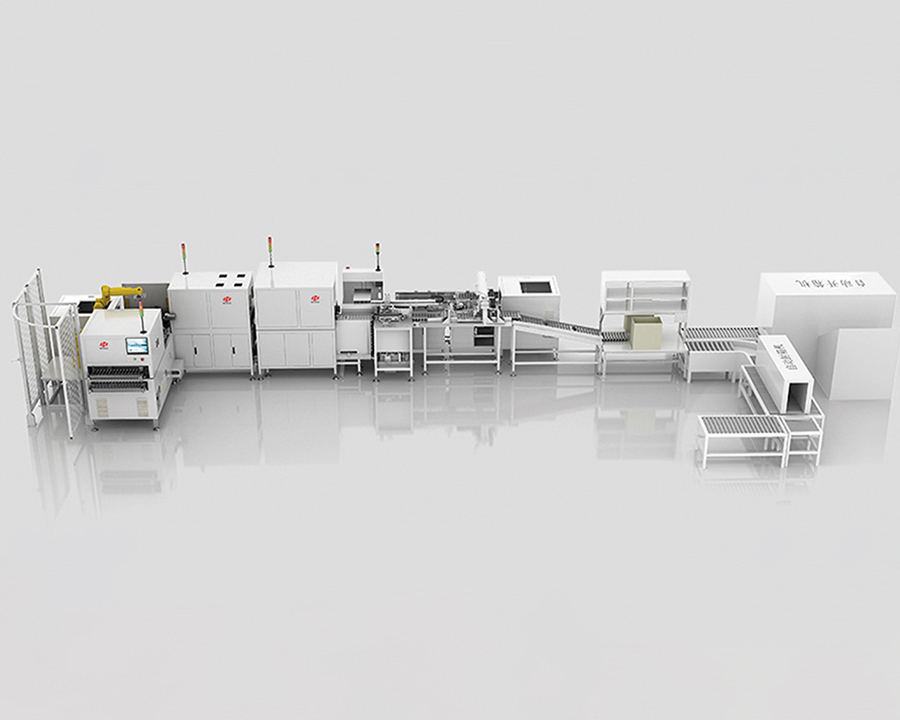

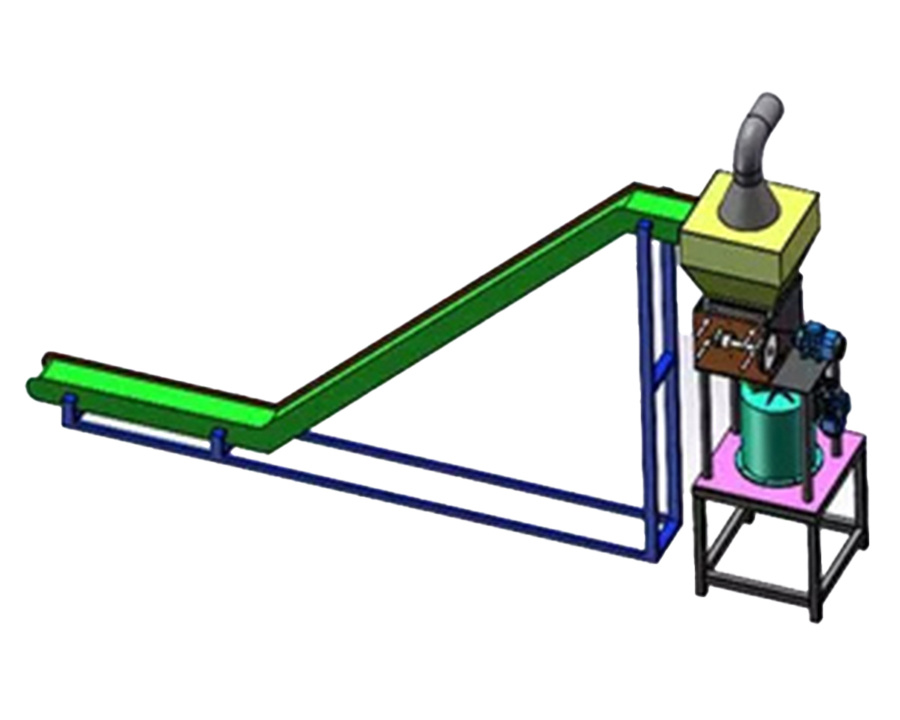

The efficient design concept is reflected in the rapid response and efficient processing capabilities of the equipment. Modern assembly and testing equipment usually adopts modular design, which can quickly adjust the equipment structure and process flow according to different assembly requirements, so as to achieve rapid switching and efficient production of multiple relay models.

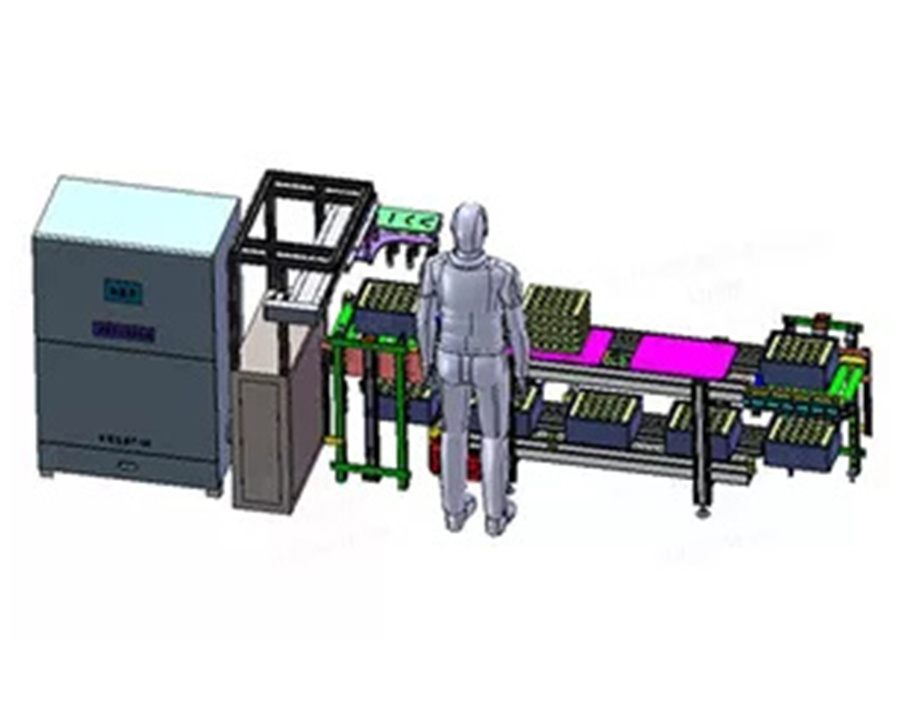

The quality of automotive relays is directly related to the overall performance and safety of the car. Therefore, it is very important to accurately detect and strictly control the relays during the assembly process. Modern automotive relay assembly and testing equipment has achieved comprehensive testing of various performance indicators of relays by introducing high-precision sensors and advanced detection technology.

In addition to accurate detection, modern assembly and testing equipment also has strict quality control capabilities. The equipment strictly controls every link in the assembly process through preset quality standards and testing procedures to ensure that each relay meets high quality standards. In addition, the equipment can also record and analyze the test data in real time, providing strong support for subsequent quality traceability and improvement.

With the continuous development of autonomous driving technology and the continuous expansion of the new energy vehicle market, the application prospects of automotive relay assembly and testing equipment will be broader. Intelligent equipment will be able to better adapt to the safety and reliability requirements of autonomous driving vehicles, and ensure the stable operation of the automotive electrical system through real-time monitoring and early warning systems.

Automotive relay assembly and testing equipment plays a pivotal role in the modern automotive industry. Driven by both technological innovation and quality assurance, the equipment will continue to upgrade and improve, providing strong support for the intelligent and new energy development of the automotive industry. In the future, with the continuous advancement of technology and the continuous expansion of the market, the application prospects of automotive relay assembly and testing equipment will be even broader.

English

English русский

русский عربى

عربى