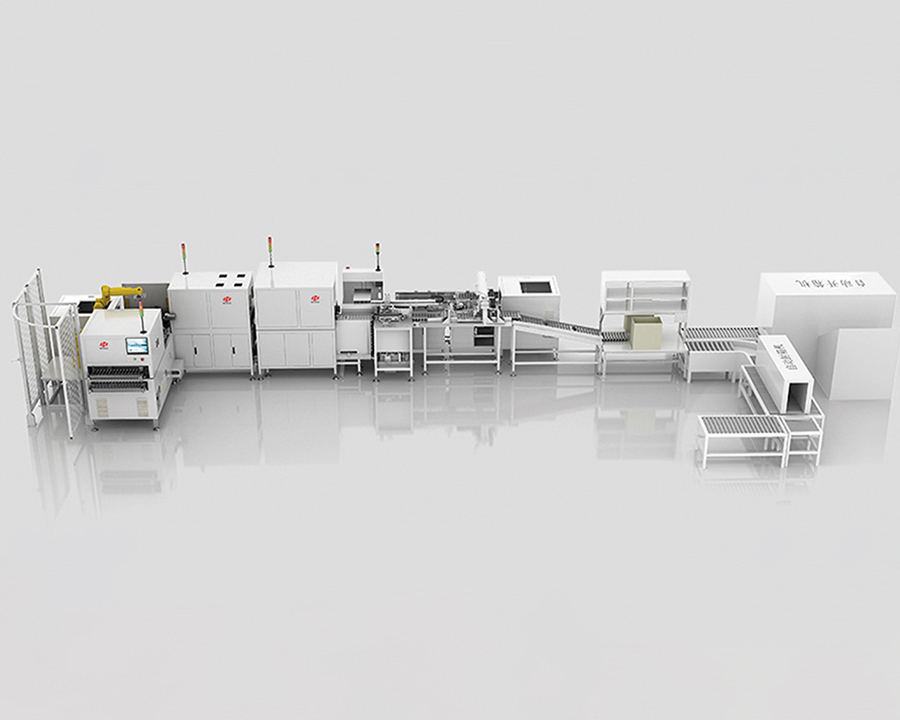

Energy storage automated production line: a disruptor for the future energy industry?

Energy storage automation production line represents an important technological development direction in the energy industry. With the increasing global demand for renewable energy and the emphasis on energy storage technology, energy storage automation production line is developing rapidly and will play a more important role in the future.

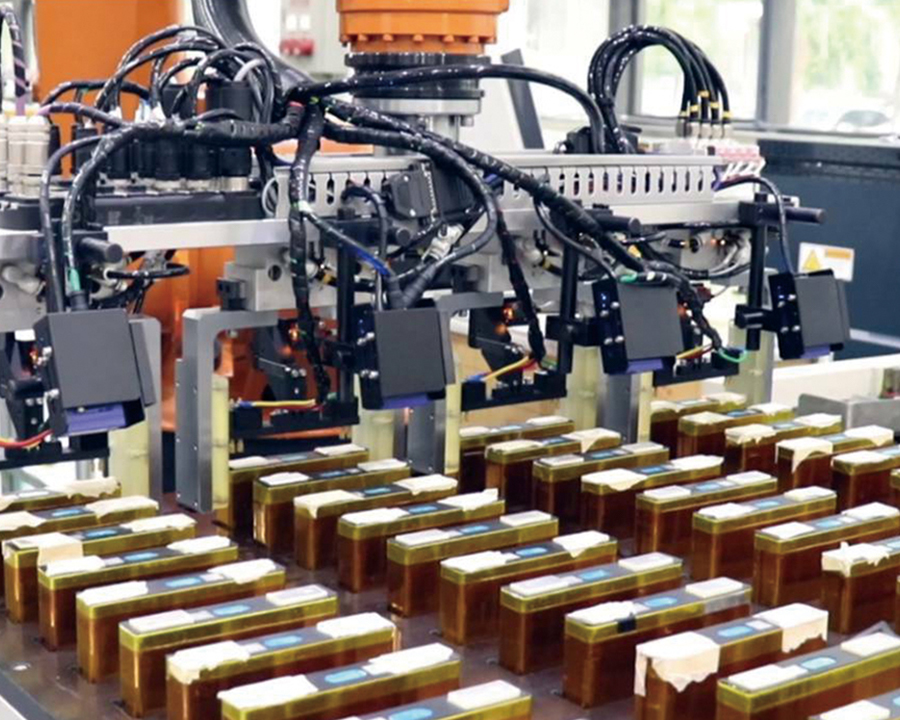

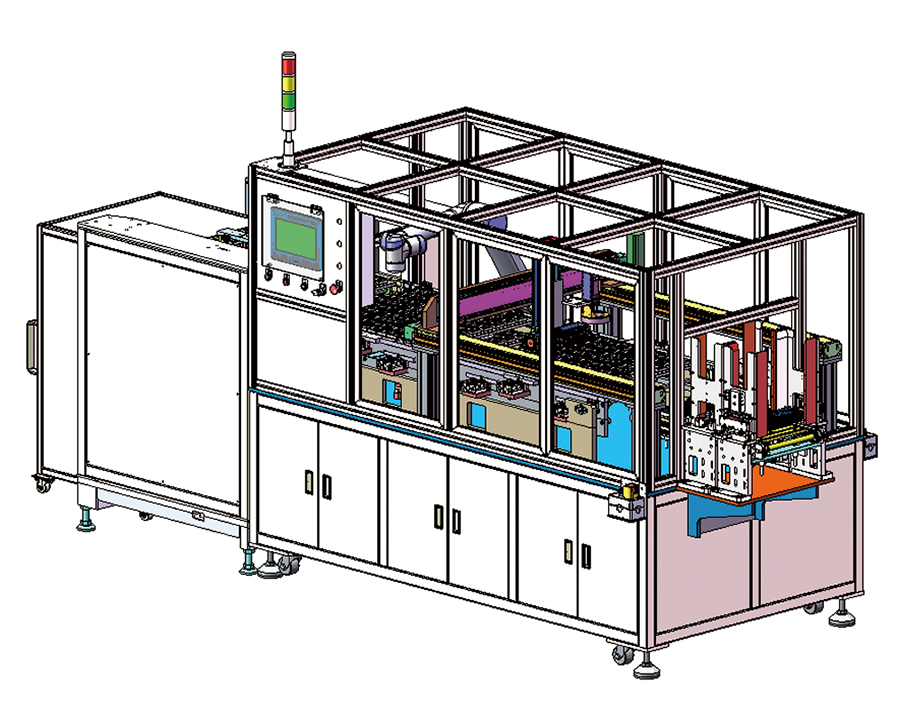

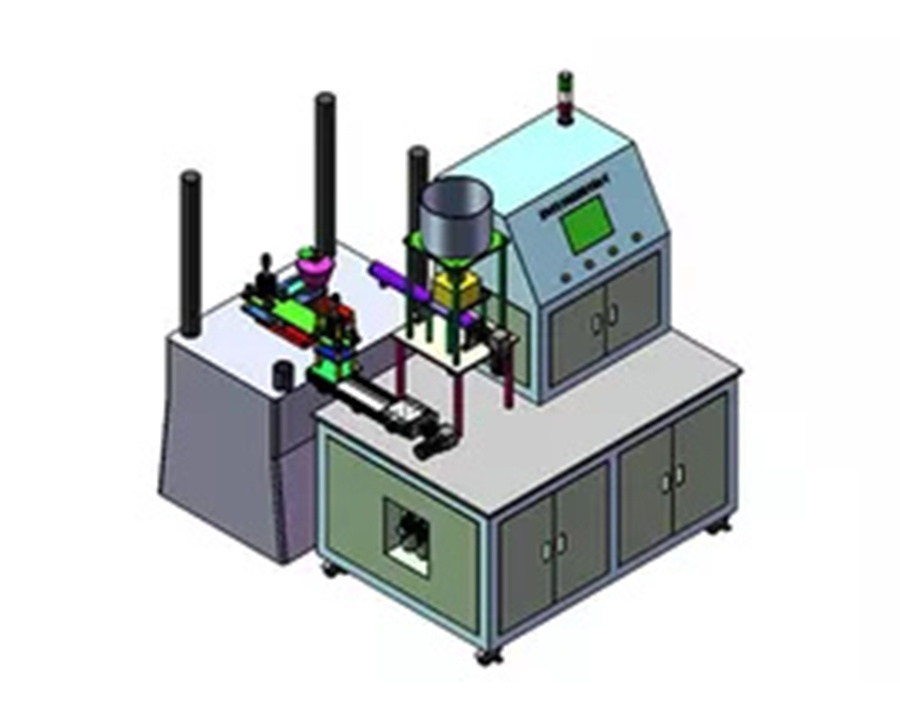

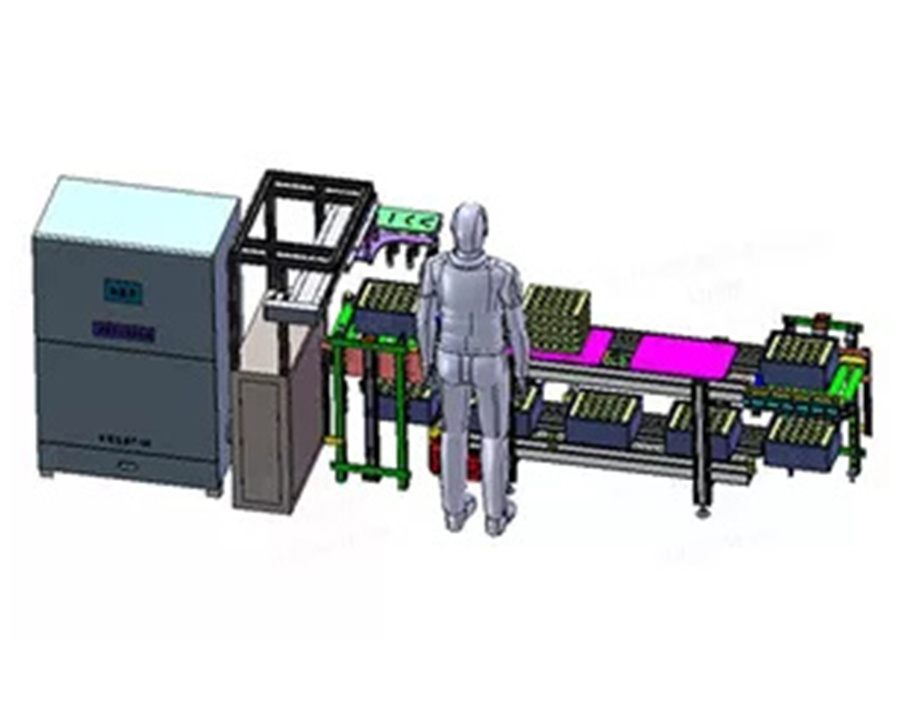

With the continuous advancement of science and technology, automation technology will play an increasingly important role in energy storage production lines. The continuous development of intelligent robots, automated control systems and various sensor technologies will make energy storage production lines more intelligent and efficient. For example, intelligent robots can complete more complex assembly and testing tasks, while automated control systems can achieve real-time monitoring and adjustment of the production process, thereby improving the production efficiency and product quality of the production line.

With the widespread application of big data and artificial intelligence technology, energy storage automation production lines will pay more attention to data collection, analysis and utilization. Through the analysis of production data, enterprises can find bottlenecks and problems in production and make targeted optimizations. By analyzing a large amount of production data, it is possible to find the inefficiency of a certain production link or the optimization space of a certain process parameter, thereby further improving production efficiency and product quality.

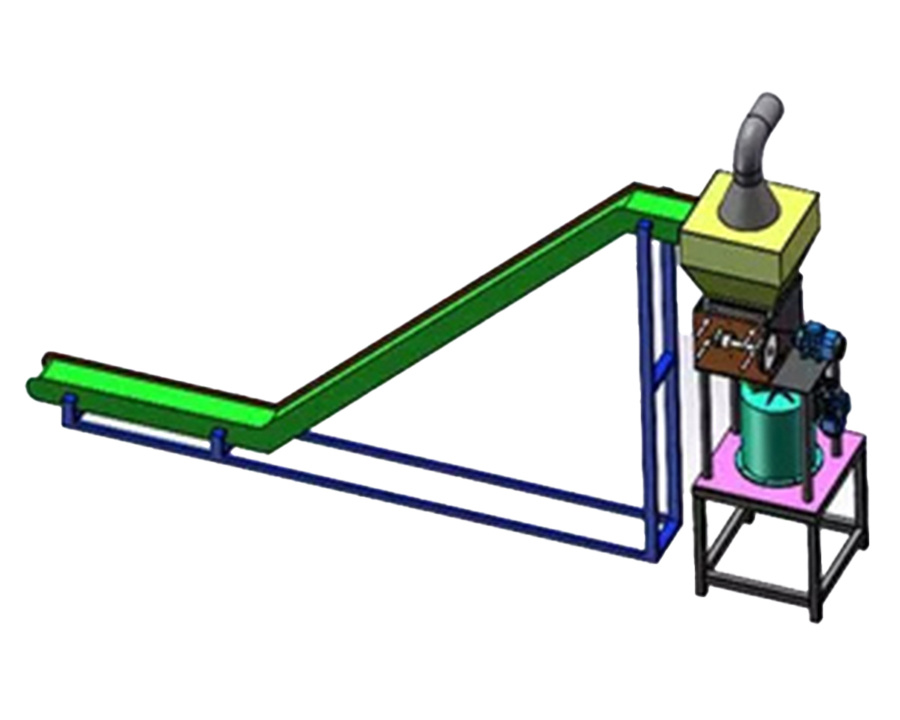

The continuous emergence of new materials and new processes brings new development opportunities for energy storage automation production lines. New battery materials and structural designs will further improve the energy density and cycle life of batteries, thereby promoting the continuous improvement of the performance and cost of energy storage products. At the same time, the application of new processes will also make production lines more flexible and efficient. For example, the use of 3D printing technology can achieve more complex product design and customized production.

With the continuous development of information technology, energy storage automation production lines will achieve more intelligent management. By introducing advanced production management systems (MES), enterprise resource planning systems (ERP) and warehouse management systems (WMS), enterprises can achieve all-round monitoring and management of the production process, thereby improving the operational efficiency and production capacity of the production line.

In the future, energy storage automation production lines will pay more attention to environmental protection and sustainable development. As the world's attention to environmental pollution and climate change continues to increase, companies will actively promote the greening and low-carbonization of production lines. Measures such as using clean energy to supply electricity, reducing production waste emissions and improving energy utilization efficiency will become an important direction for the development of energy storage production lines.

The future development of energy storage automation production lines will be affected by automation technology, big data, new materials and environmental protection. By continuously introducing new technologies, optimizing production processes and strengthening environmental protection, energy storage automation production lines will make more important contributions to the sustainable development of the energy industry and global energy transformation.

English

English русский

русский عربى

عربى