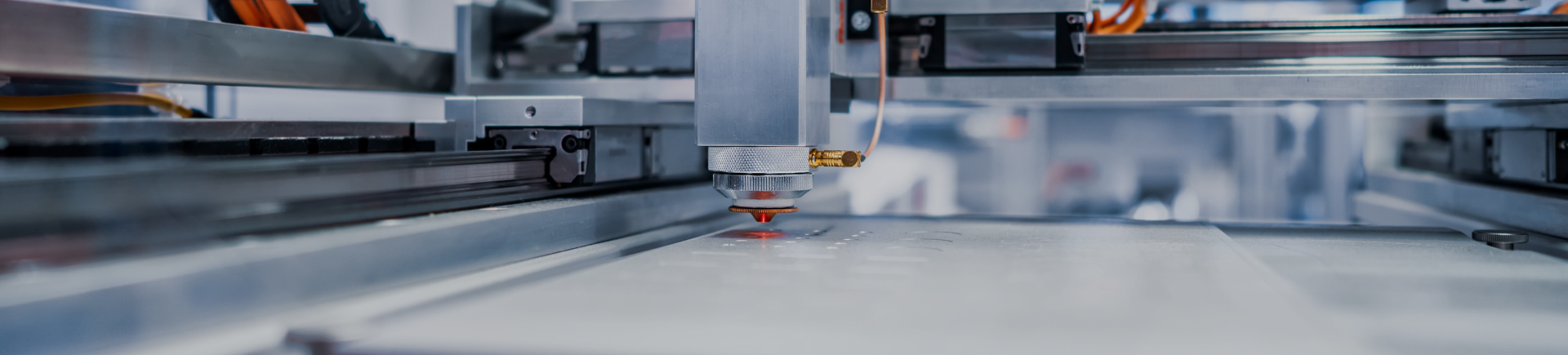

Amid the industrialization of third-generation semiconductor materials, silicon carbide (SiC) has become an essential material for new energy vehicles, 5G communications, photovoltaic power generation...

READ MORE

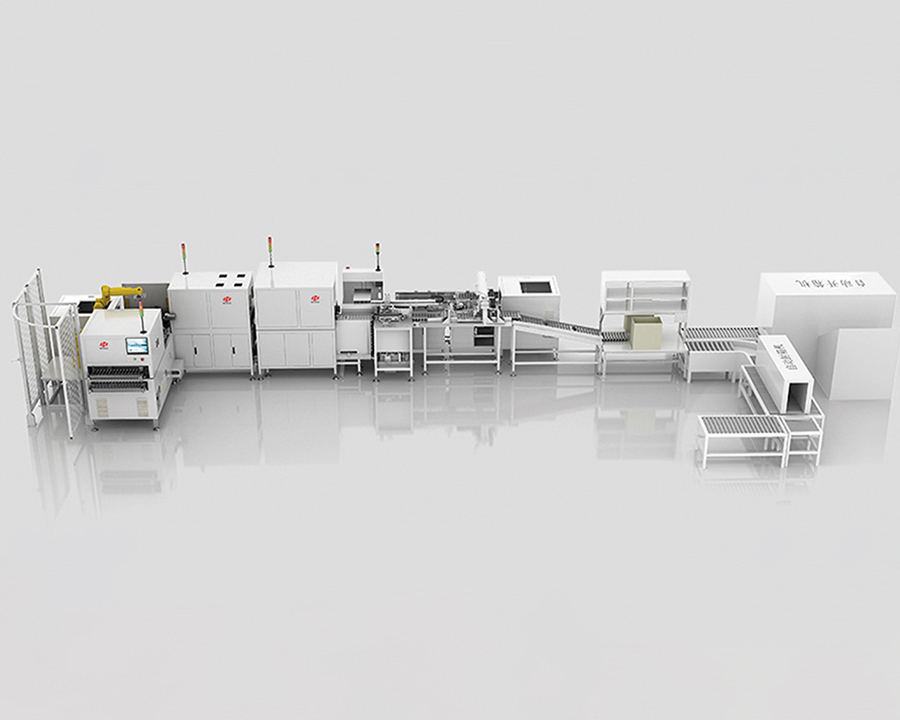

Energy storage automated production line

Kunli Company is a qualified supplier of lithium battery equipment and non-standard equipment for CATL. The automatic assembly line for energy storage containers and battery families we have developed will greatly improve the efficiency of energy storage PACK assembly automation and achieve industrial scale mass production.

At present, when assembling battery packs in energy storage containers, of them are assembled manually inside the container, which is not only inefficient but also poses major safety and quality risks. Based on such problems, Kunli Company researched and developed the automated packaging of energy storage batteries, providing a solution for the automated assembly of energy storage containers. The automated solution can increase the original assembly automation efficiency by more than 35%.

2. Kunli provides design, R&D and manufacturing solutions for energy storage PACK aluminum liquid cooling trays

At present, aluminum energy storage trays are formed by profile welding. The process is complex and has poor reliability. Aluminum alloy profiles are welded and formed. There are as many as dozens of processes and there are a large number of welds, which greatly reduces the strength and reliability of the box. The heat transfer medium is discontinuous, resulting in poor heat dissipation performance of the box and high manufacturing cost.

Kunli Company uses the light alloy material manufacturing technology of the new energy company and integrates the technical strength of the research school to develop and design an integrated low-pressure casting forming solution for energy storage boxes for energy storage manufacturing companies: using aluminum alloy low-pressure casting integrated forming. and cooling pipe pre-embedded technology. The cooling effect of the cooling pipe is reliable and the leakage prevention ability is strong, which significantly improves the heat dissipation of the box and reduces the manufacturing cost by about 12%.

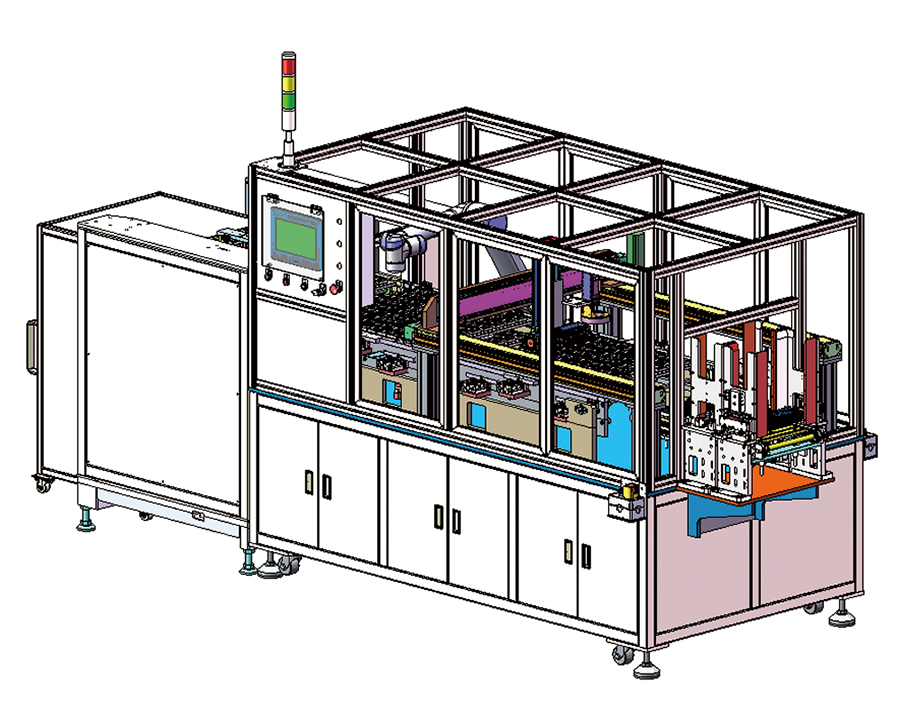

3. Automation of energy storage production line assembly line

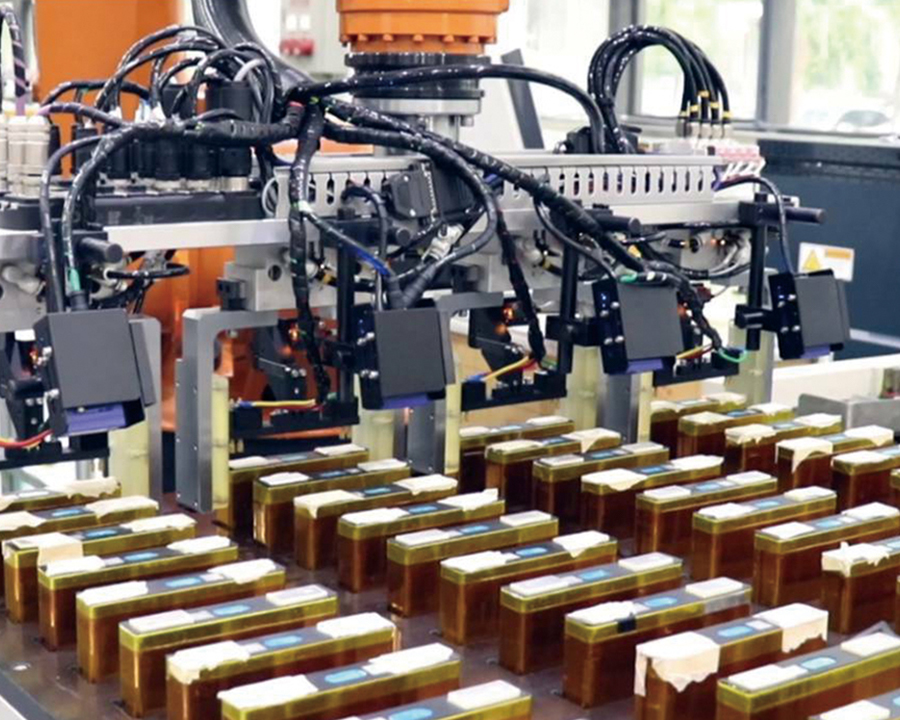

In the entire assembly process from single cells to automated modules to PACK production and assembly lines, the degree of automation in assembly is an important factor in determining product quality and production efficiency. Kunli Company provides technical upgrades and transformations for energy storage battery clusters and battery stack assembly lines. At the same time, it provides an automated battery cluster assembly line for energy storage, which includes automatic loading and unloading, cell sorting, intelligent warehousing, module assembly and other processes. It has a high degree of automation and work efficiency.

Who are we?

Established in 2013, Liyang Kunli Machinery Manufacturing Co., Ltd is a scientific and technological enterprise specializing in the R&D, transformation and production of industrial automation equipment and non-standard automation equipment. We are china Energy storage automated production line Suppliers and Energy storage automated production line Manufacturers, Factory. Equipped with dozens sets of precision machining equipment for machining, cutting and welding,etc, the company now has more than 20 design engineers, 5 software and PLC electrical engineers, 3 inspectors, and 16 key CNC technicians. Kuli company has been engaging in the innovation of automatization technology and solution to automatization, so as to promote the progress of the technology of smart factories, non-standard equipment and automated assembly lines. The company has made many technological breakthroughs and achieved success in the projects of high precision equipment, unmanned smart factories, etc, in the course of many years’research and development, and therefore a good range of high-tech, high-precision, cutting-edge products have been designed, developed and produced. The scope of R&D includes the following area: 1. Unmanned smart factories, flexible automation lines, non-standard auto equipment; the design and production of non-standard automatization of assembly lines, intelligent storage, stacking, palletizing and transportation, etc. 2. Stirring, coating, coiling, soft pack sealing, Lithium battery cleaning and assembling in the industry of new energy lithium battery and energy storage; the production process of automatization of energy storage assembly lines, etc. 3. The design of inspection robots(inspection of safe production, fire and water prevention, malfunction of equipment, etc), unmanned automated patrol scheme and relevant turn-key projects. 4. The integrated design of automatization of CCD vision . 5. The design of automatization scheme of AGV handling and integration projects. 6. The design of non-standard customized equipment, special equipment and automation production lines and relevant turn-key projects. Kunli company has been devoting to the R&D and innovation of high precision, cutting-edge equipment for more than a decade, and has accumulated rich technological experience in R&D and manufacture.

-

Advanced Plant Ared

0㎡+ -

Founded In

0 -

Designers

0+ -

Technical Backbone

0+

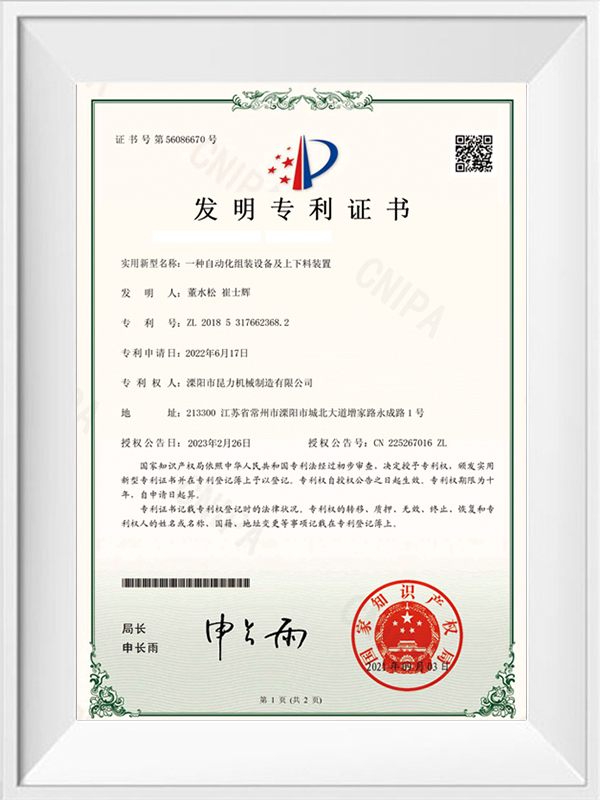

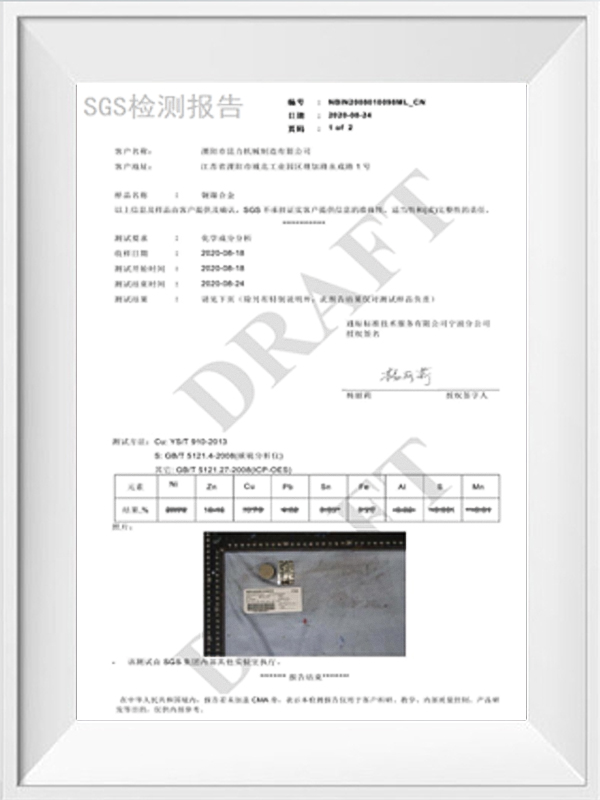

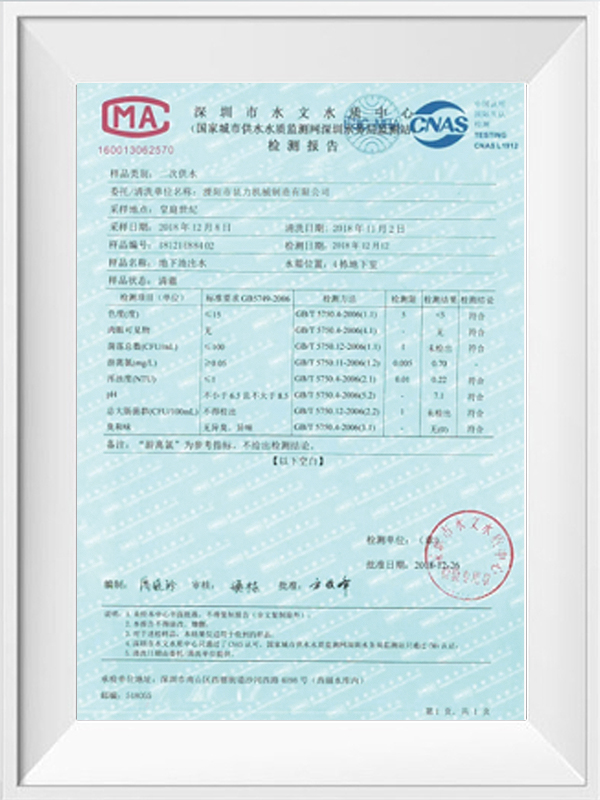

Qualifications we have obtained

Authentic reliable quality naturally stands out and fears no comparison. Professional Energy storage automated production line Suppliers.

-

-

Accurately measuring an object's tilt is crucial in many industries, and inclinometers shoulder this crucial mission. In recent years, China-made clinometers have emerged in the global market, demonst...

READ MORE -

The efficient transmission and distribution of electricity is crucial in the vast networks of modern industry and infrastructure. Busbar assembly lines, as a critical link in the power system, often r...

READ MORE

English

English русский

русский عربى

عربى