How does the Standard Automated Production Line achieve an automated production process from yarn to finished product?

In the production process of textiles, how does the Standard Automated Production Line achieve an automated production process from yarn to finished product, including weaving, printing and dyeing, and finishing?

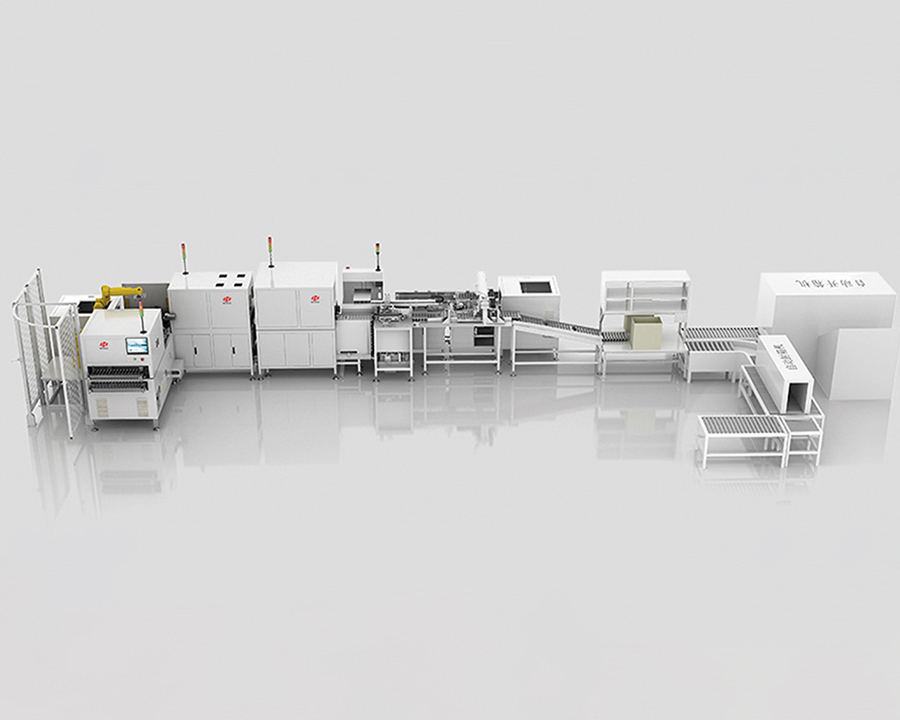

In the production process of textiles, the Standard Automated Production Line integrates a variety of technical means and advanced equipment to achieve an automated production process from yarn to finished product, covering key processes such as weaving, printing and dyeing, and finishing. The following are specific implementation methods:

1. Spinning stage

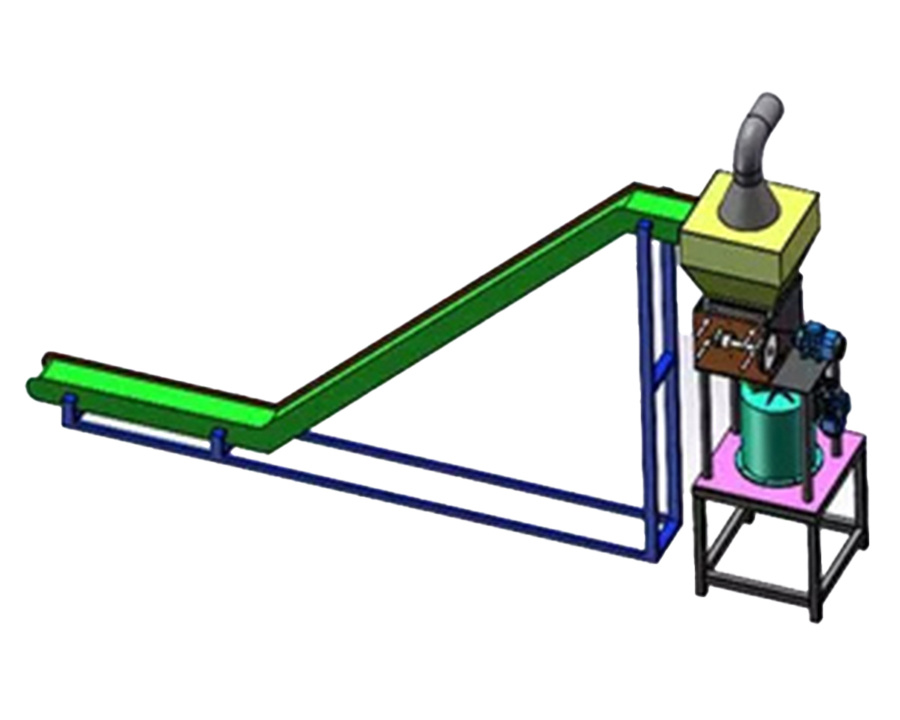

Fiber processing: Fibers are cleaned, opened and combed by automated equipment to remove impurities and make the fibers finer and more uniform.

Fiber spinning: Fibers are converted into yarns using automated spinning machines, and spindles are formed through stretching and spinning processes.

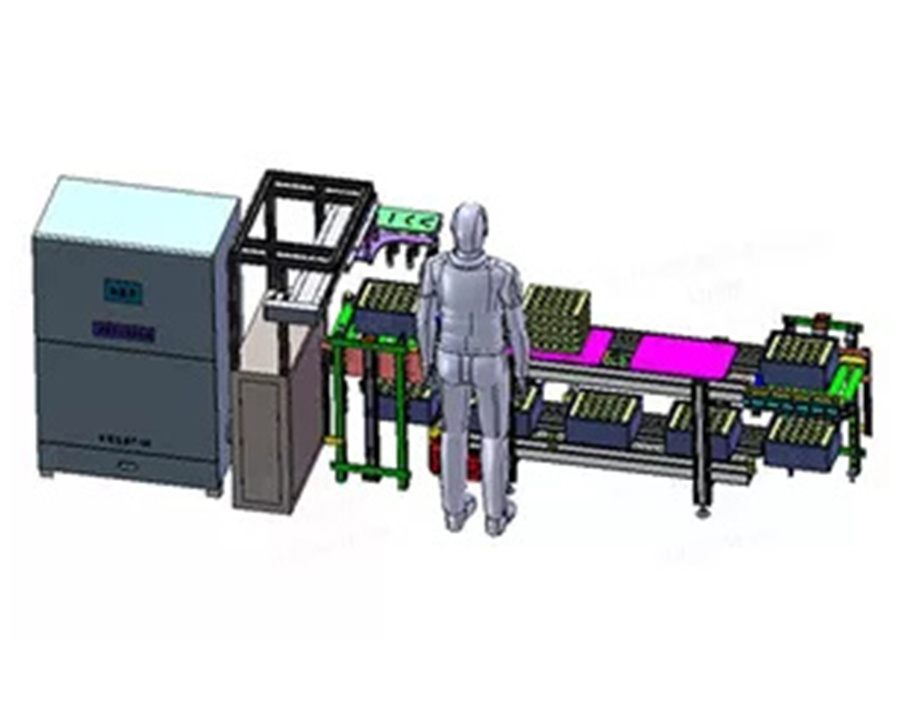

2. Weaving stage

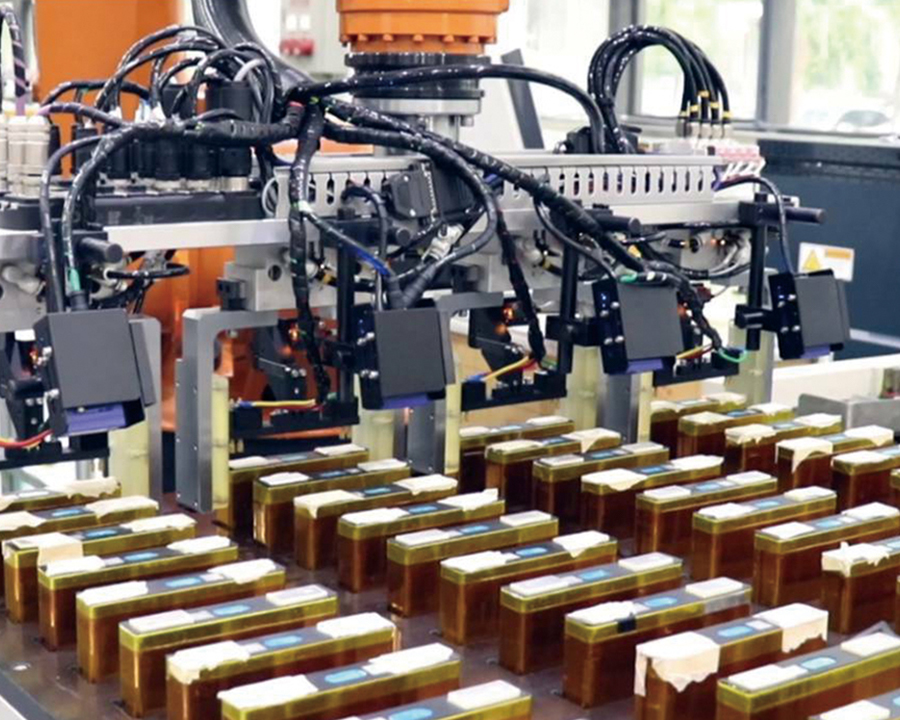

Weaving preparation: Yarns are screened using automated equipment to ensure that the yarn quality and specifications meet the fabric requirements, and the yarns are automatically installed on the warp table of the loom.

Weaving process: The loom automatically weaves under program control, interweaving the warp and weft threads to form a fabric. This process is highly automated, reducing human intervention and errors.

3. Printing and dyeing stage

Pretreatment: Automated pretreatment of fabrics, including cleaning, impurity removal and pH adjustment, to prepare for dyeing.

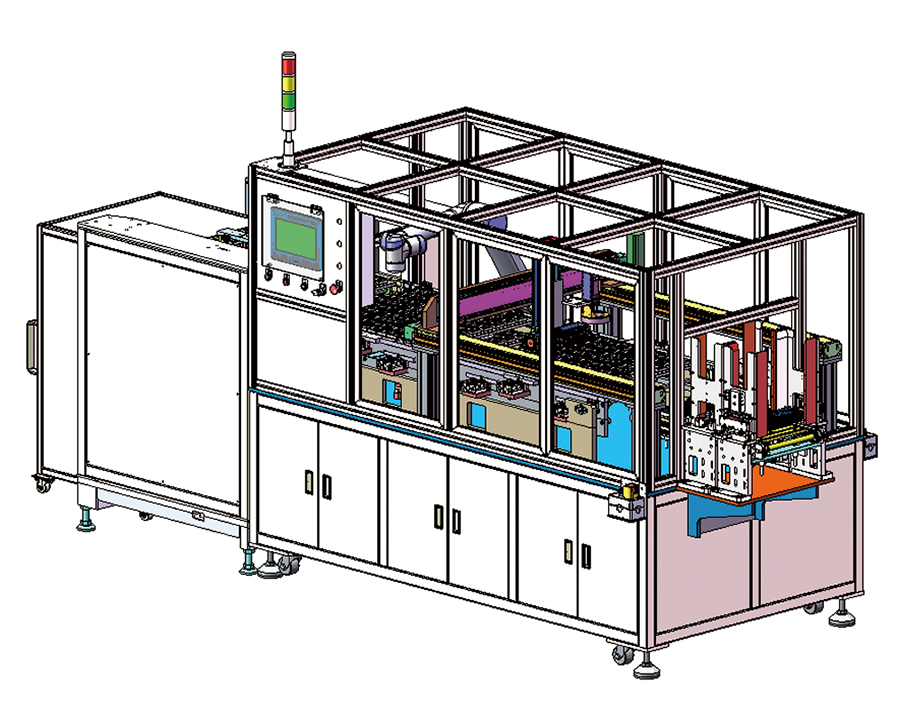

Dyeing process: Dye fabrics through computer-controlled dyeing machines, and select appropriate dyes and dyeing methods according to the required color and effect. The automated dyeing system can accurately control the dyeing temperature, time and dye concentration to ensure uniform and accurate dyeing.

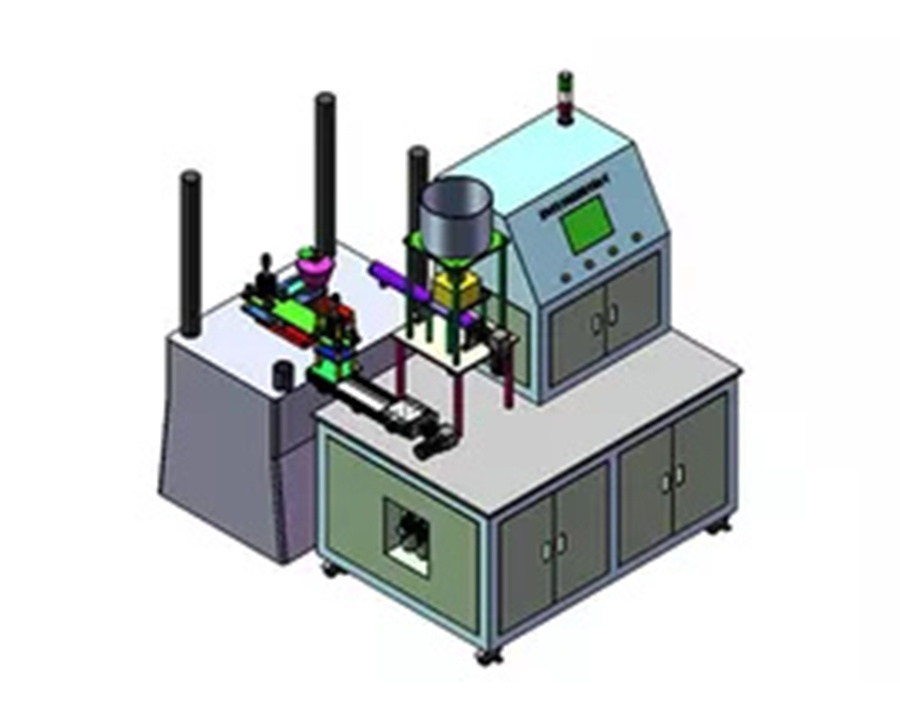

4. Finishing stage

Pre-finishing treatment: Automated drying of dyed fabrics to make them soft and smooth.

Finishing process: Use automated equipment to perform calendering, hemming, and trimming on fabrics to improve the appearance and feel of fabrics.

Final finishing: Quality inspection through automated equipment to ensure that the finished fabrics meet quality standards. Automated packaging is performed as needed to prepare for shipment or enter the next production link.

Throughout the automated production process, Standard Automated Production Line uses sensors, actuators, program controllers, and data communications to achieve automatic control and collaborative operations in each link. These technical means ensure the stability and reliability of the production process and improve production efficiency and product quality. At the same time, automated production lines also reduce labor intensity, improve working conditions, and bring significant competitive advantages to textile production.

English

English русский

русский عربى

عربى