How do non-standard automated production lines optimize food processing and packaging processes?

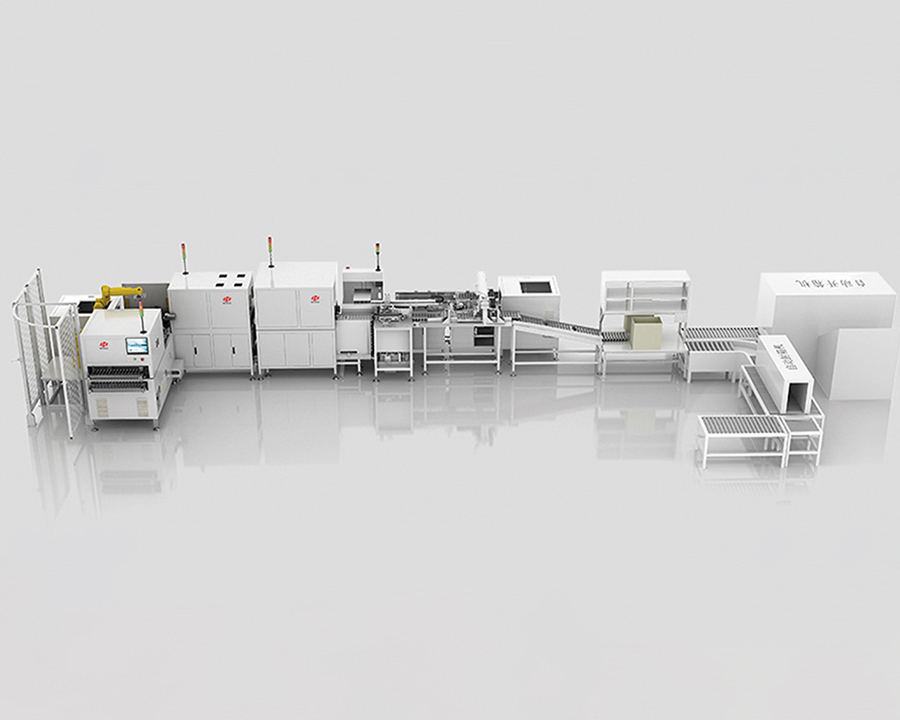

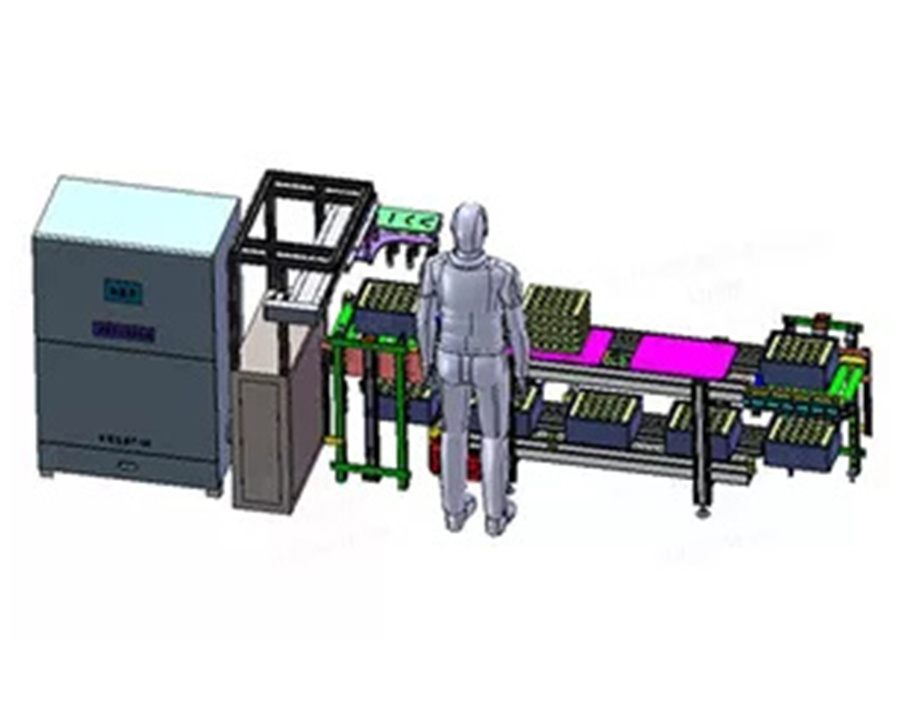

In the food industry, non-standard automated production lines can accurately meet the needs of food processing and packaging processes through customized design, thereby optimizing the entire production process and improving production efficiency and product quality. The following are specific optimization measures:

1. Optimization of food processing processes

Process analysis and standardization:

Carefully analyze each process in the food processing process to identify potential problems and room for improvement.

Establish standardized operating procedures and operating specifications to ensure that each employee operates in accordance with standards and reduce the impact of human factors on the production line.

Equipment transformation and upgrading:

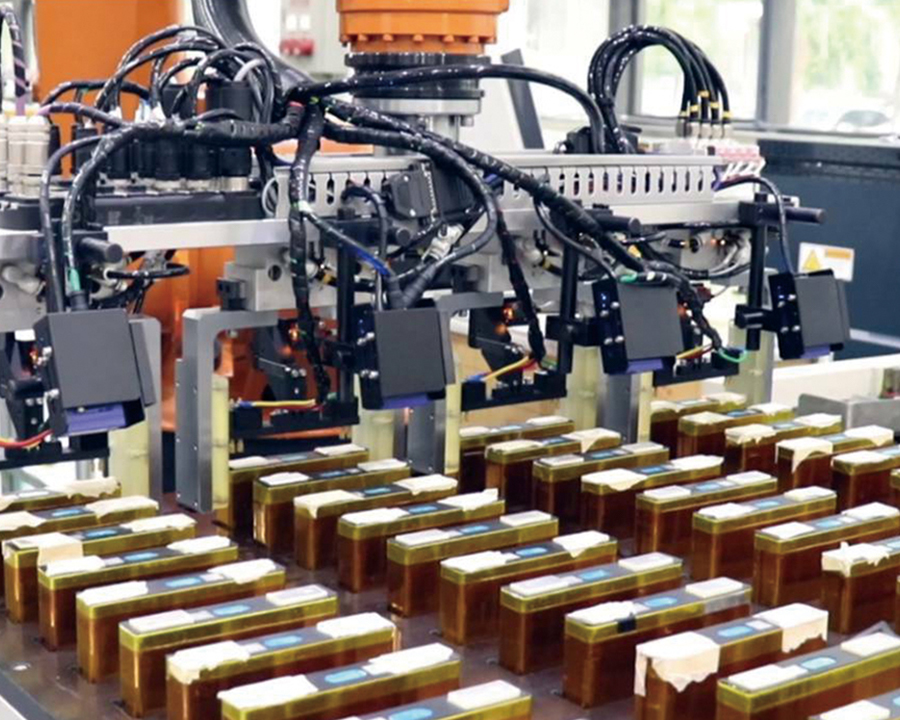

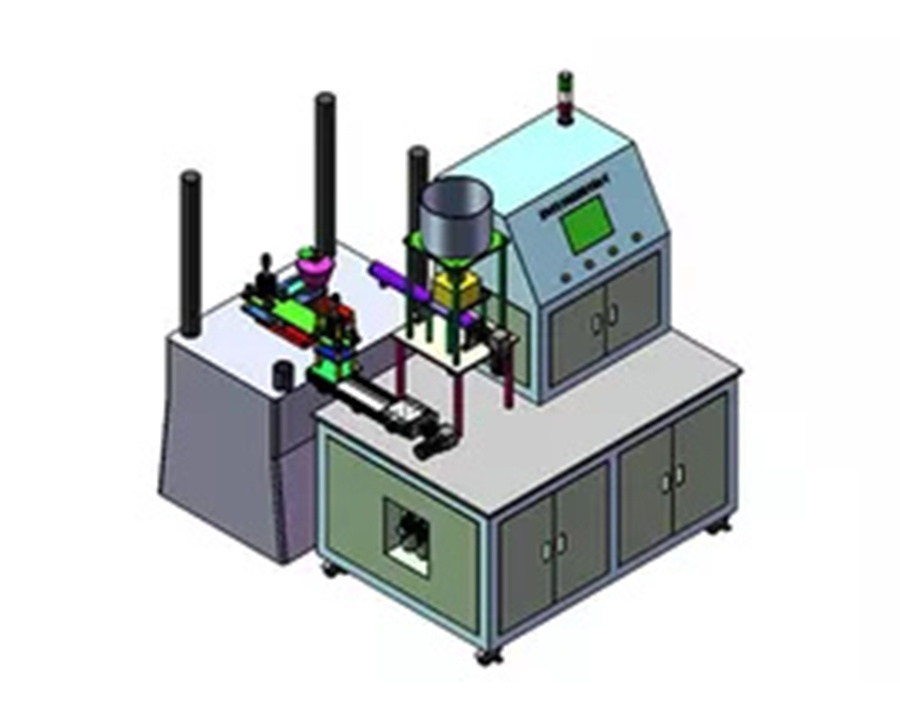

Introduce automated equipment, such as automated cutting machines, mixers, etc., to reduce manpower input and improve production efficiency.

Apply intelligent technologies, such as the Internet of Things and artificial intelligence, to achieve real-time monitoring and analysis of production data, timely identify problems and take measures to adjust and optimize.

Raw material processing:

Automated processing of raw materials, such as cleaning, cutting, peeling, etc., to improve the processing efficiency and quality of raw materials.

Ensure the accuracy and consistency of raw materials during processing through sensors and control systems.

2. Optimization of the packaging process

Automated packaging machines:

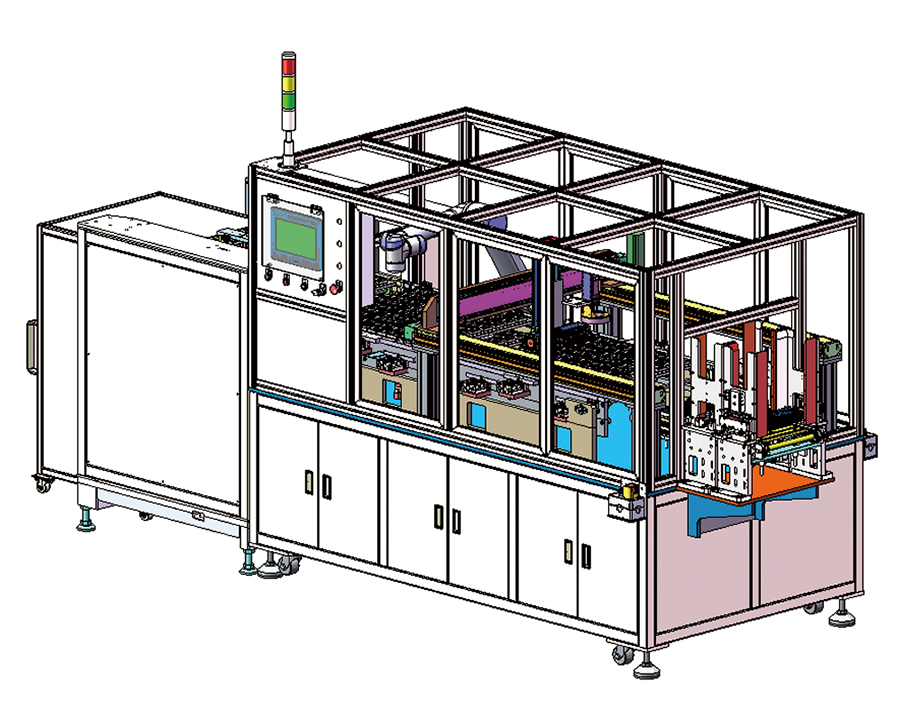

Introduce automated packaging machines, such as automatic cartoning machines, sealing machines, etc., to automate the packaging process and improve packaging speed and consistency.

Automated packaging machines use intelligent technology to reduce the production content of material mixing and handling during the packaging process, and reduce the error rate of manual operation.

Selection of packaging materials:

Choose packaging materials that meet the application of your own products, such as environmentally friendly, non-toxic and durable packaging materials, to ensure the safety of the products.

Automated production lines can be quickly adjusted according to the requirements of packaging materials to meet the packaging needs of different products.

Quality inspection and control:

Establish a strict quality inspection system, and use automated equipment and systems to conduct quality inspections on packaged products to ensure that product quality meets standards.

Real-time collection and analysis of production data, monitoring and adjustment of the packaging process, to ensure the stability and consistency of product quality.

3. Overall optimization effect

Improve production efficiency:

Through the application of non-standard automated production lines, food processing and packaging processes have achieved a high degree of automation and intelligence, significantly improving production efficiency.

Reduce the impact of manpower input and human factors, and reduce production costs.

Improve product quality:

Standardized operating procedures and operating specifications ensure the stability and consistency of product quality.

The application of automated equipment and systems improves the accuracy and consistency of product processing and reduces product quality issues.

Non-standard automated production lines in the food industry achieve a dual improvement in production efficiency and product quality by optimizing food processing and packaging processes. This helps companies improve their market competitiveness and meet consumers' demand for high-quality food.

English

English русский

русский عربى

عربى