How to ensure that the particle size of Silicon carbide dust-proof crushing automation equipment is always kept below 2MM?

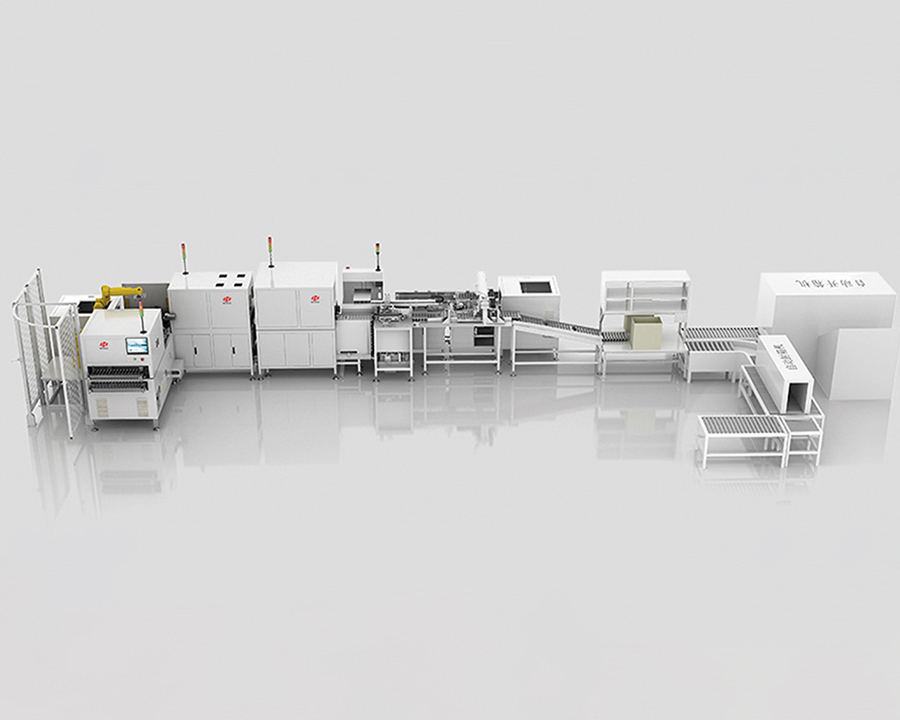

Ensuring that the particle size of Silicon carbide dust-proof crushing automation equipment is always kept below 2MM is the key to ensuring product quality and production efficiency.

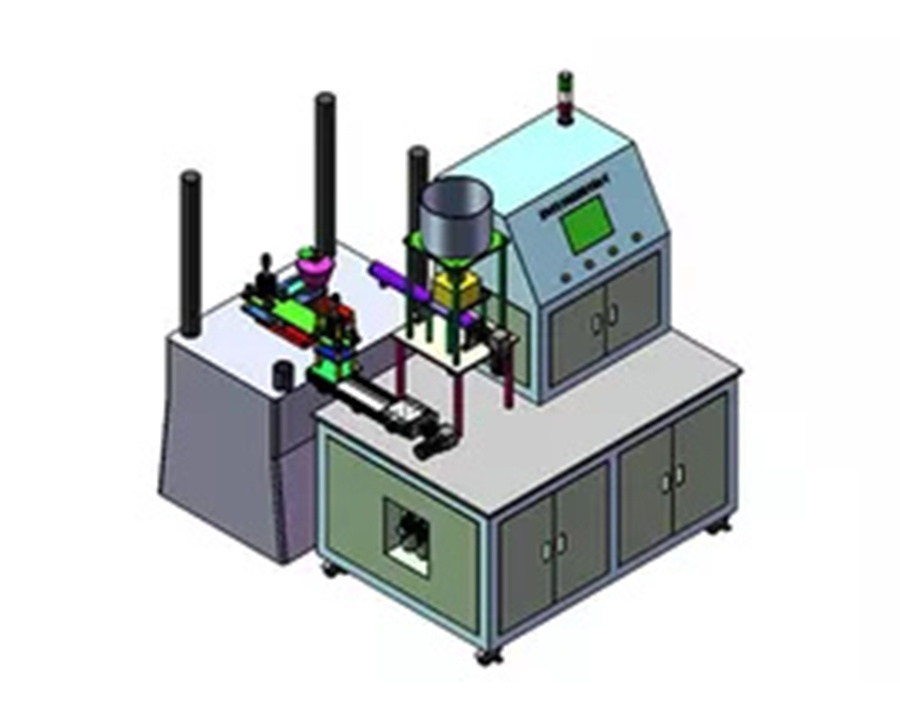

1. Equipment design and manufacturing

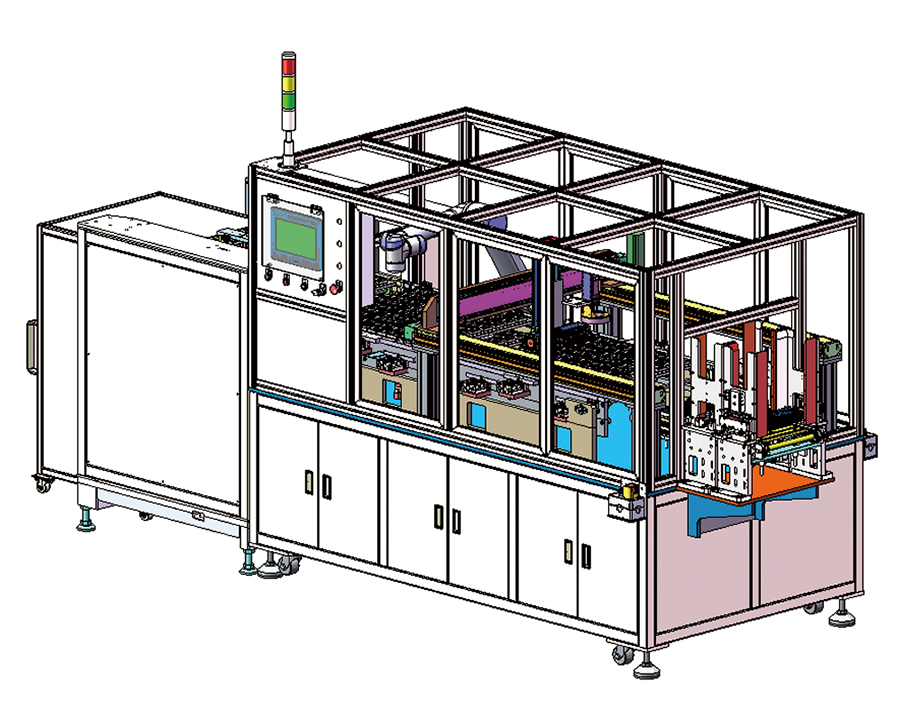

Particle size adjustment system: The particle size adjustment system is an intelligent control system integrated in Silicon carbide dust-proof crushing automation equipment. It monitors and adjusts the particle size during the crushing process in real time to ensure that the particle size of the output product meets the preset requirements. The particle size detection device monitors the particle size of the crushed product in real time. The control system receives the detection data and compares it with the preset particle size requirements. If the particle size is detected to be out of range, the control system will automatically adjust the relevant parameters of the crusher, such as reducing the rotation speed, increasing the crushing force or adjusting the feed speed. The adjusted crushing parameters will take effect immediately, so that the particle size of the product gradually approaches the preset requirements. The whole process is continuous and dynamic, ensuring that the product particle size always remains in a stable state.

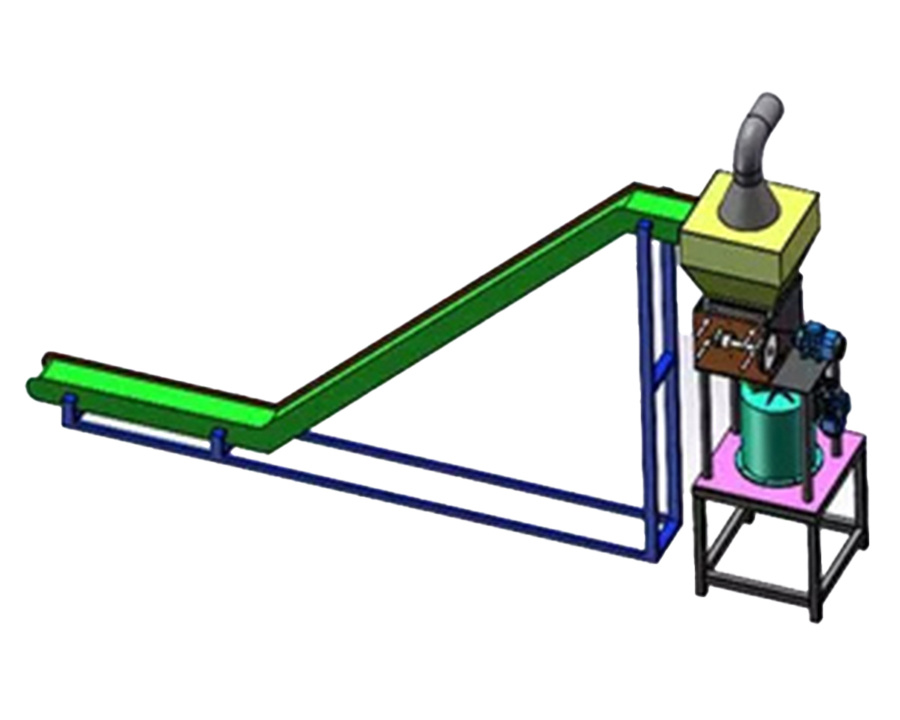

Crushing chamber design: The structure and size of the crushing chamber are crucial to particle size control. By optimizing the design of the crushing chamber, such as adopting a reasonable crushing ratio and feed port design, the particle size distribution of the product can be effectively controlled.

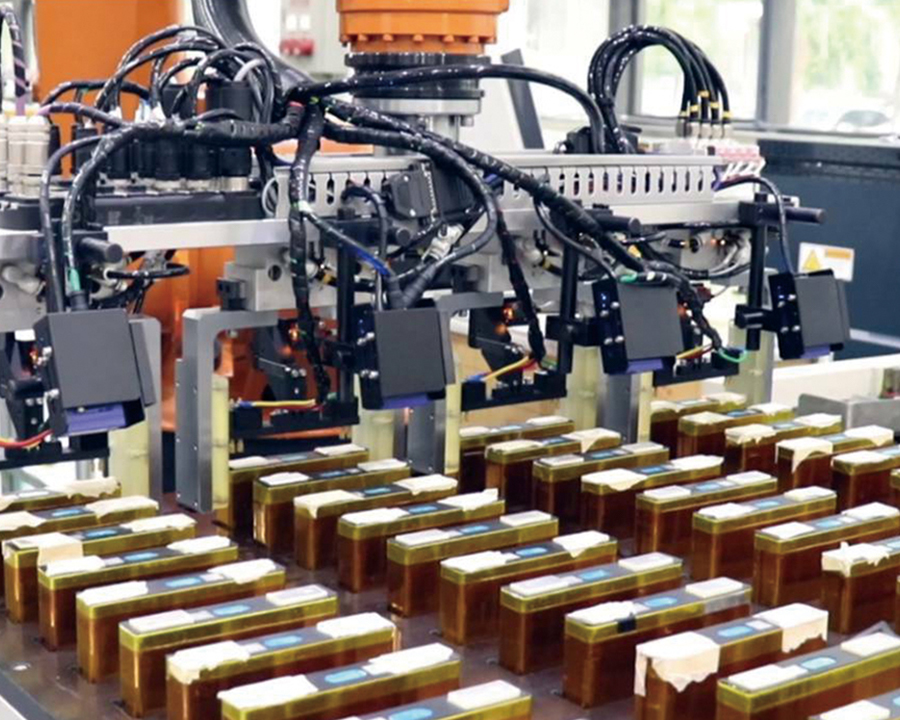

Crushing media: According to the physical properties of Silicon carbide, select appropriate crushing media (such as hammers, blades, etc.). These media should have high hardness and wear resistance to ensure that the crushing effect can be maintained in a stable state during long-term operation.

2. Control system

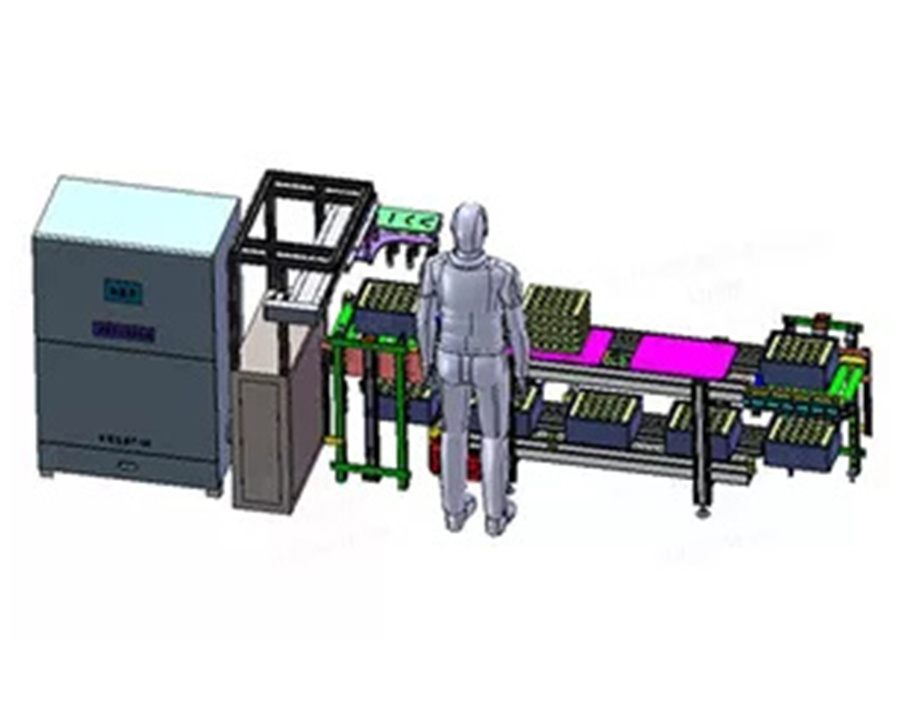

Automatic control system: Integrate advanced automatic control systems to realize the automatic operation and monitoring of Silicon carbide dust-proof crushing automation equipment. The system can automatically adjust the relevant parameters (such as rotation speed, crushing force, etc.) in the crushing process according to the set particle size requirements to ensure stable particle size.

Intelligent detection and feedback: Install a particle size detection device in the equipment to monitor the particle size of the product in real time. When the particle size is detected to be beyond the set range, the system can automatically adjust the crushing parameters and give corresponding feedback prompts.

3. Operation and maintenance

Operation specifications: Develop detailed operation specifications and require operators to operate the equipment strictly in accordance with the specifications. Especially when adjusting the particle size, ensure that the adjustment is made in accordance with the prescribed steps and parameters.

Regular maintenance: Regularly maintain and service the equipment to ensure the normal operation of the equipment and the accuracy of the particle size adjustment system. In particular, the particle size detection device and crushing media are regularly inspected and replaced to ensure their stability and reliability.

Training and guidance: Train and guide operators to improve their operating skills and troubleshooting capabilities. At the same time, operators are required to be proficient in the control system and particle size adjustment system of the equipment so that they can flexibly respond to various situations in actual operation.

IV. Material management

Feed control: Strictly control the quality and particle size of the feed. For materials that do not meet the requirements, pretreatment or screening should be carried out to ensure that the materials entering the crushing chamber meet the requirements of the equipment.

Discharge detection: Regularly test the discharge to ensure that the particle size of the product is always kept below 2MM. For unqualified products, the equipment parameters should be adjusted in time or secondary crushing should be carried out.

To ensure that the particle size of Silicon carbide dust-proof crushing automation equipment is always kept below 2MM, it is necessary to start from multiple aspects such as equipment design, control system, operation and maintenance, and material management.

English

English русский

русский عربى

عربى