Wire Harness Machine: Efficient innovation in manufacturing

In modern manufacturing, Wire Harness Machine (wire harness manufacturing equipment), as an efficient and precise electromechanical equipment, is gradually changing the traditional model of wire harness production. It not only improves production efficiency, but also significantly improves product quality and safety.

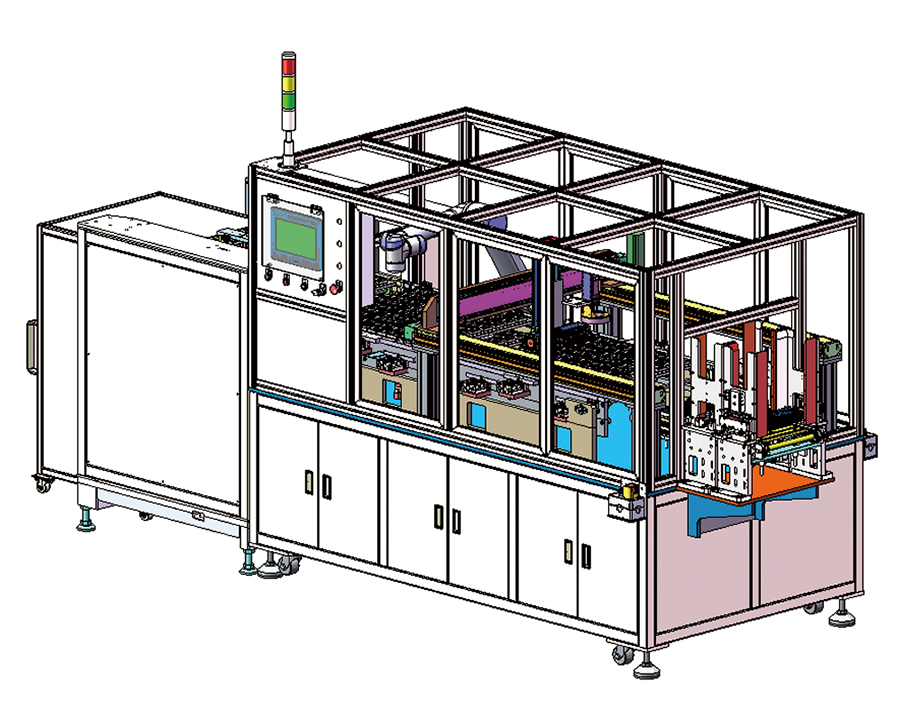

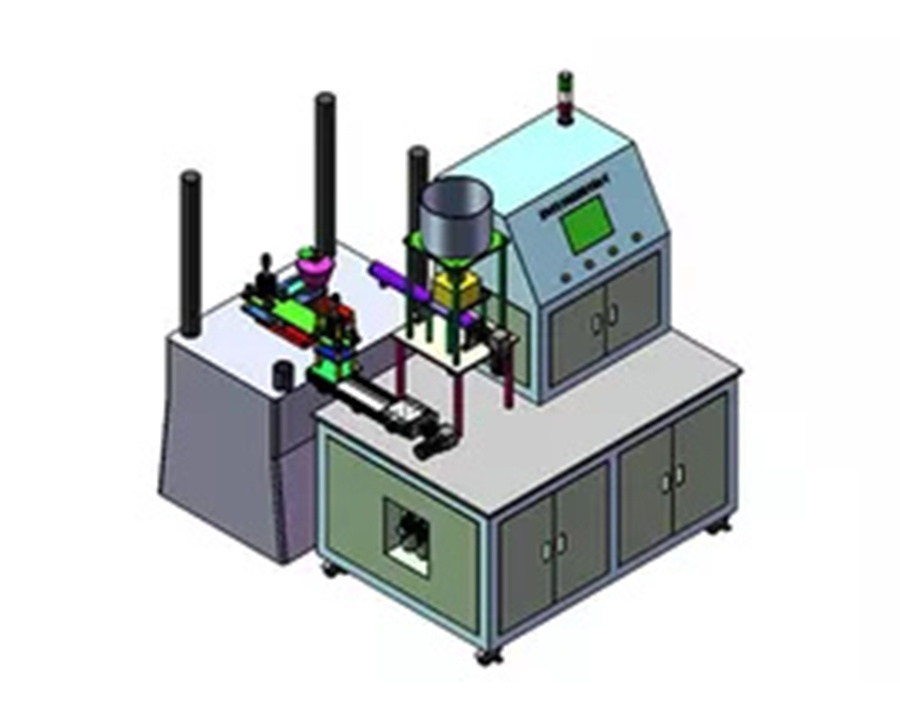

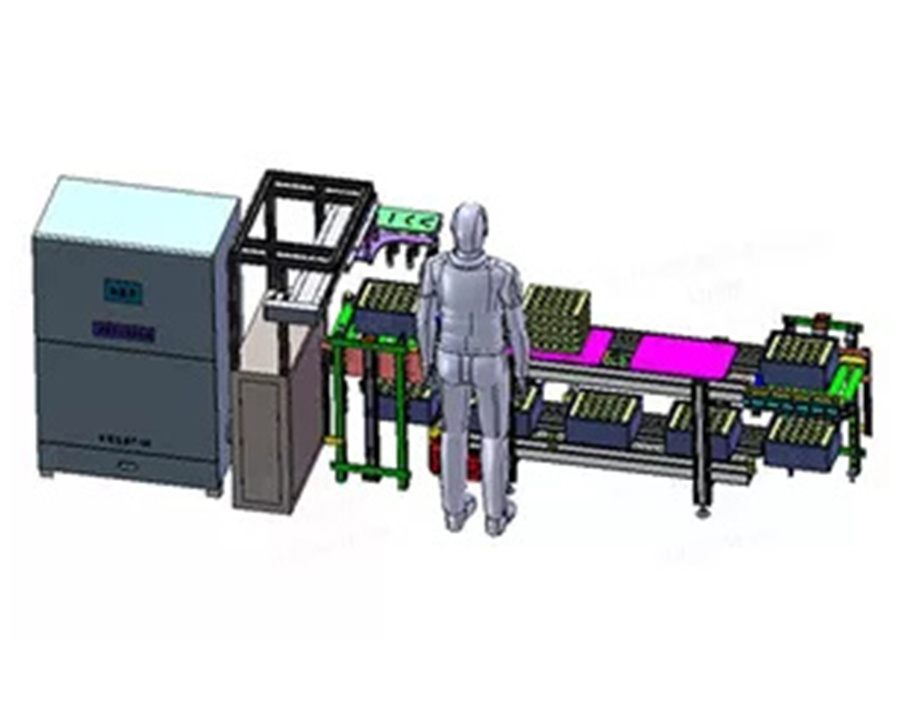

Wire Harness Machine, also known as braiding machine, is mainly used to braid single wires into wire bundles to facilitate subsequent installation, laying and maintenance. The process is highly automated and typically consists of multiple workstations, each completing a different manufacturing step.

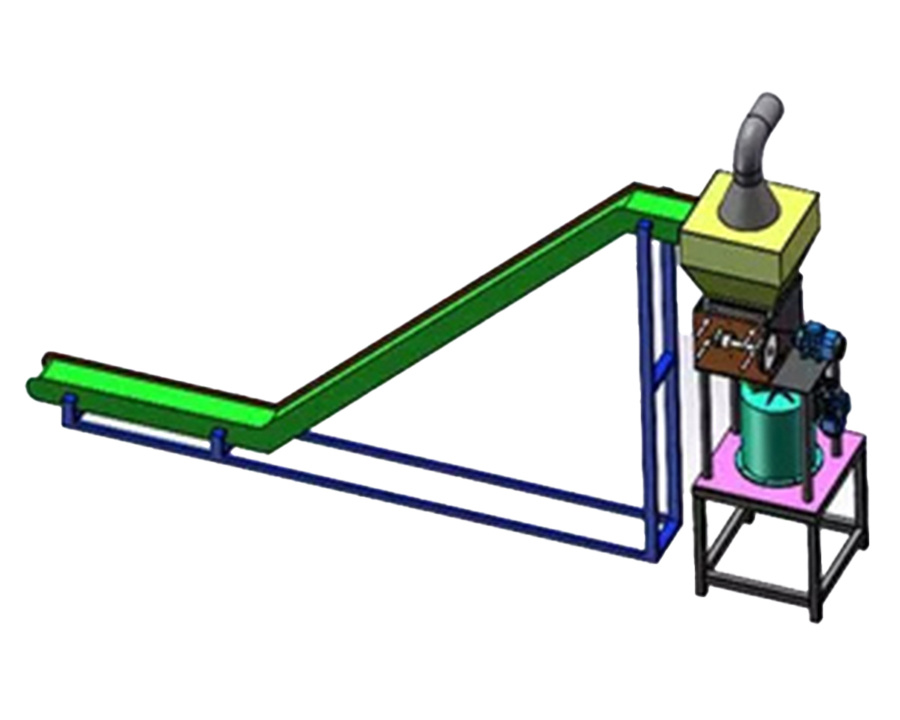

Wire storage rack and copper wire stretching device: The equipment first stores a large amount of wire through the wire storage rack, and then performs preliminary processing of the wire through the copper wire stretching device.

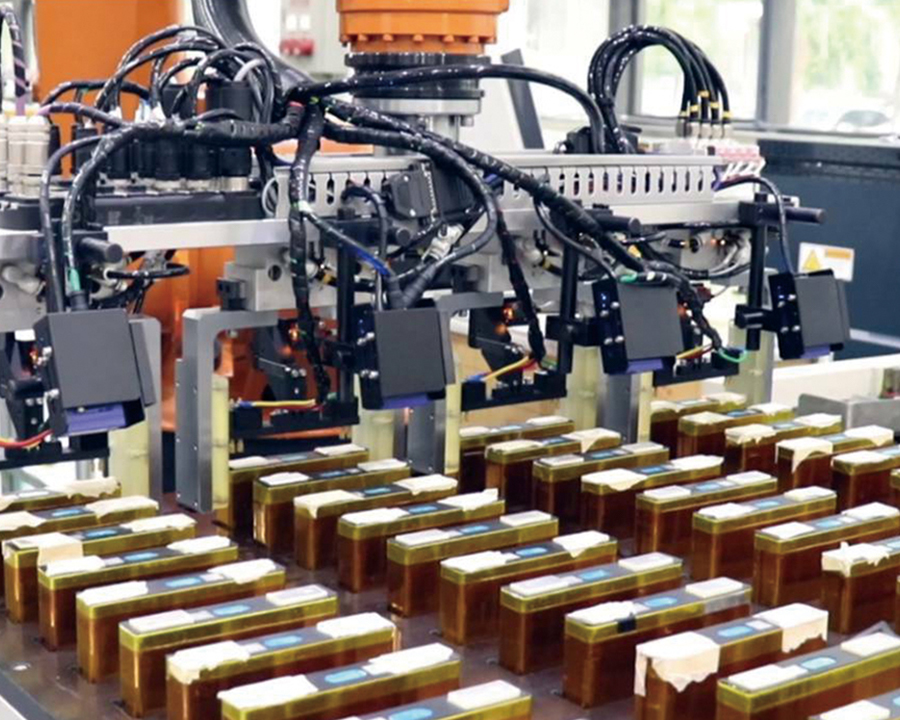

Positioner and braiding head: After the wire is accurately positioned by the locator, it is braided by the braiding head. The design of the braiding head ensures that the wire remains tight and even during the braiding process.

Cable transfer mechanism and wire take-up rack: The braided wire harness is transferred to the wire take-up rack through the cable transfer mechanism for sorting and storage.

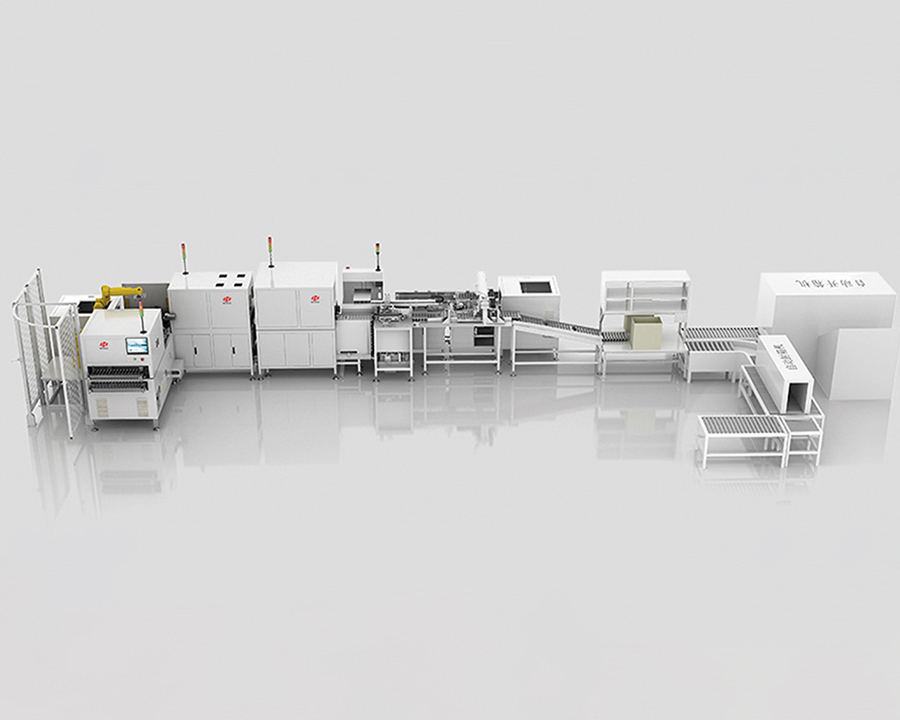

On the automated production line, Wire Harness Machine is also equipped with other key equipment, such as terminal inserters, automated wire loaders, ultrasonic welding machines, etc., which work together to complete the complete production process from wire to wire harness.

Wire Harness Machine is widely used in manufacturing fields such as electronic appliances, automobiles, and machinery. Especially in the automotive industry, Wire Harness is an important part of the automotive electrical system, responsible for the transmission of power and signals. Therefore, high-quality Wire Harness is vital to your car's performance and safety.

Automotive industry: The complex electrical system inside a car requires a large number of wiring harnesses to connect various components. Wire Harness Machine can efficiently produce these wire harnesses, ensuring the stability and reliability of automotive electrical systems.

Electronic and electrical industry: In electronic and electrical products, wiring harnesses also play an important role. Wire Harness Machine can customize and produce wire harnesses of various specifications and lengths according to the needs of different products.

Mechanical industry: The electrical control part of mechanical equipment also requires a large number of wire harnesses to connect various sensors and actuators. The automated production capabilities of Wire Harness Machine make the production of these wire harnesses more efficient and accurate.

Wire Harness Machine plays an increasingly important role in the manufacturing industry. With the rapid development of manufacturing industry, the demand for wire harnesses is also increasing. The traditional wire harness production method can no longer meet the needs of modern manufacturing. Wire Harness Machine has become the preferred equipment for wire harness production with its advantages of efficiency, accuracy and safety.

English

English русский

русский عربى

عربى