Automatic Flag-Making Machine: Revolutionizing the Flag Production Industry

In the realm of manufacturing, automation has revolutionized numerous industries, enhancing efficiency, reducing costs, and improving product quality. The automatic flag-making machine is a prime example of how technology has transformed the production of flags.

Historically, flag production was a labor-intensive process involving handcrafted techniques. Artisans would meticulously sew fabric pieces together, often relying on traditional patterns and methods. With the advent of industrialization and technological advancements, the flag-making industry began to shift towards mechanization. Automatic flag-making machines emerged as a game-changer, automating many of the manual tasks involved in flag production.

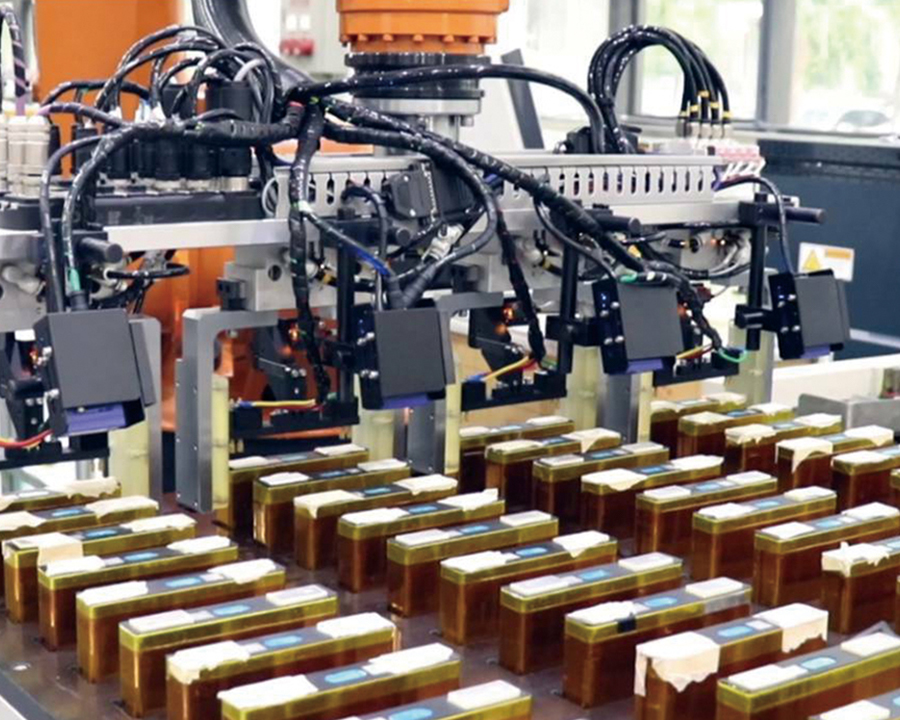

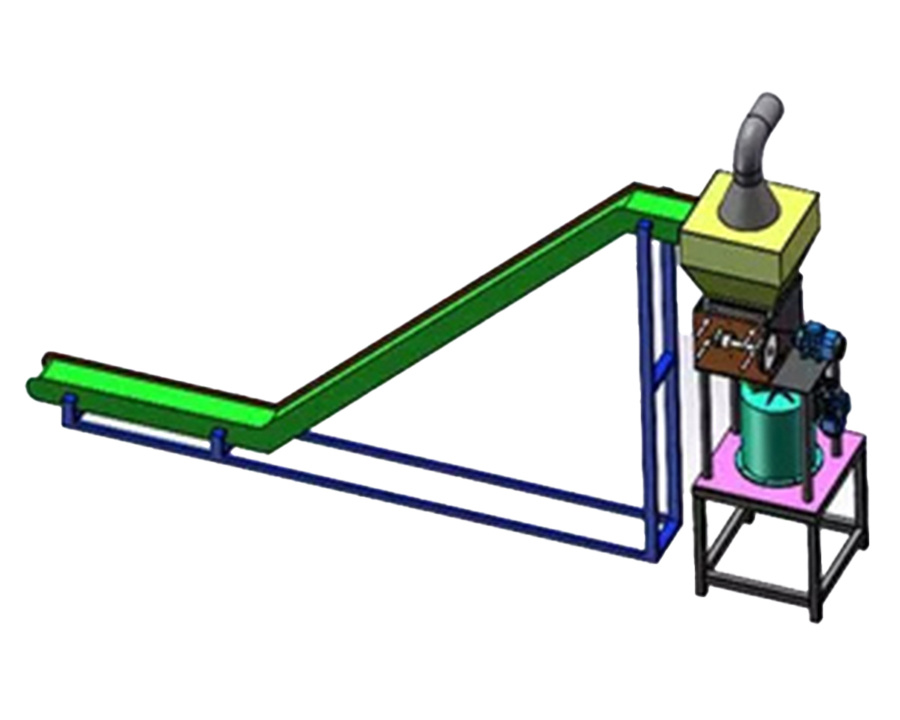

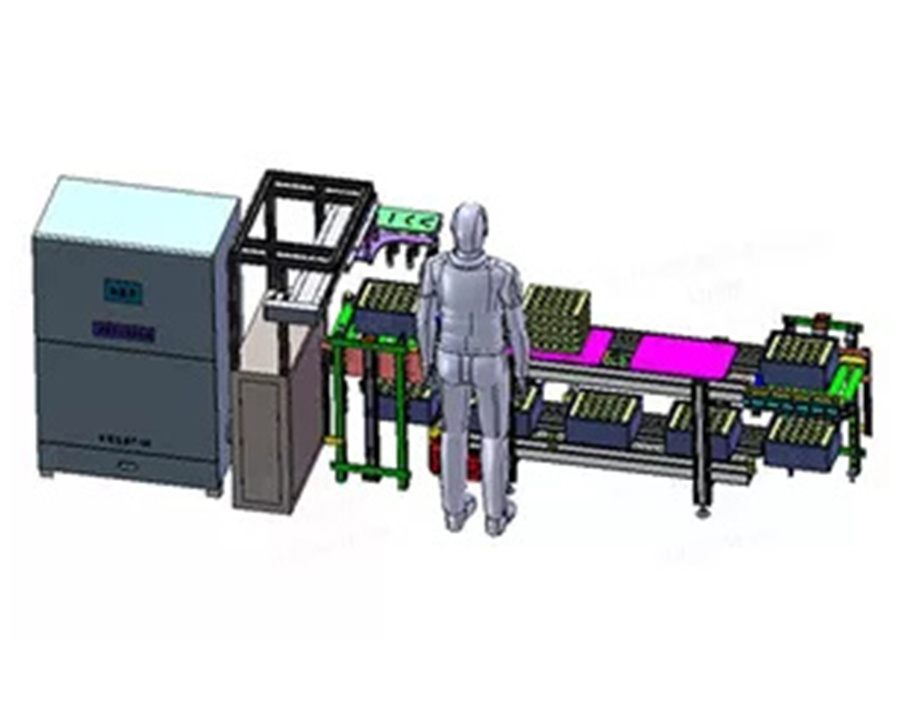

Automatic flag-making machines are designed to streamline the production process, from fabric preparation to final assembly. These machines often feature:

Roll-to-Roll Printing:

Modern automatic flag-making machines utilize roll-to-roll printing technology, allowing for continuous printing on large rolls of fabric. This eliminates the need for individual piece printing, significantly increasing production speed and reducing waste.

Sublimation Ink:

Sublimation ink is commonly used in these machines, offering vibrant, high-resolution prints that are durable and fade-resistant. This ink type is ideal for flags, as it ensures that colors remain vibrant and true over time.

Multicolor Printing:

Automatic flag-making machines can print in multiple colors, enabling the production of complex designs and patterns. This capability makes it possible to create highly customized flags that cater to specific needs and preferences.

Precision and Accuracy:

These machines are equipped with high-precision print heads, such as the EPSON I3200, capable of printing at resolutions up to 720*1200dpi. This ensures that every detail of the flag design is accurately reproduced, enhancing the overall aesthetic quality.

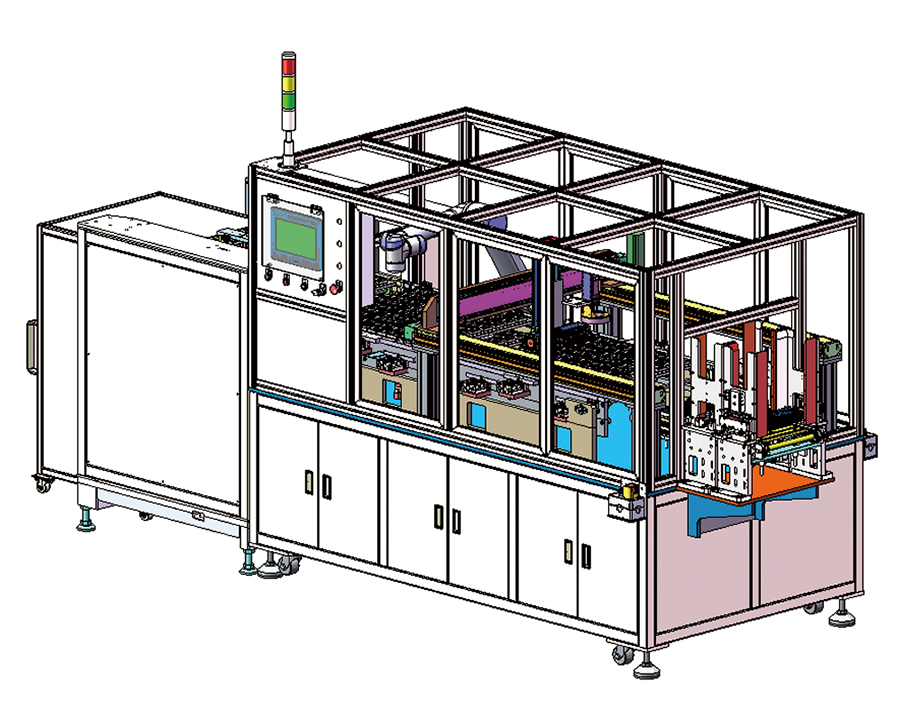

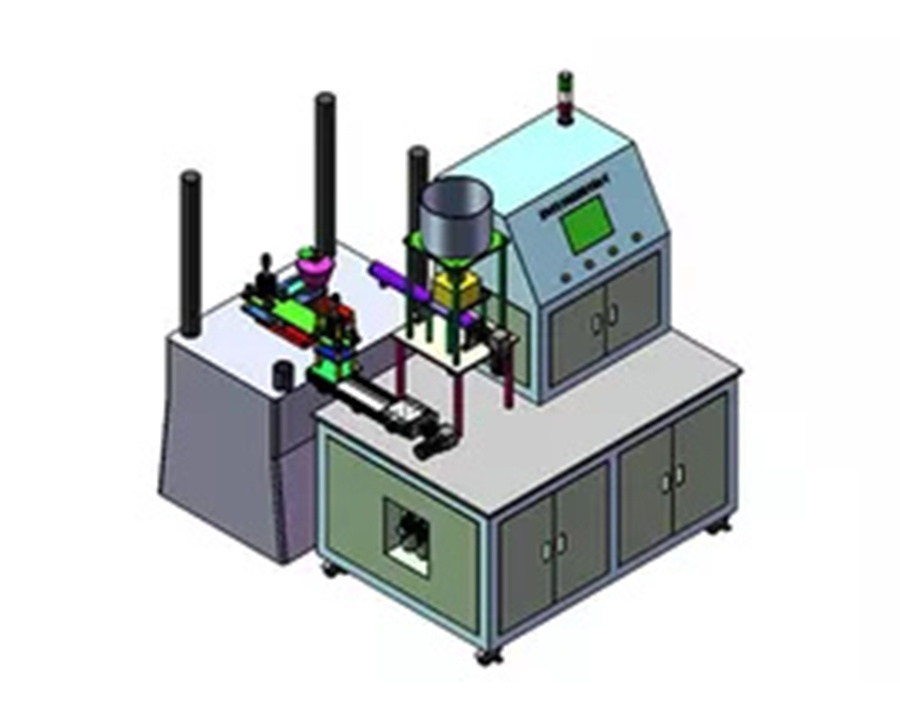

All-in-One Design:

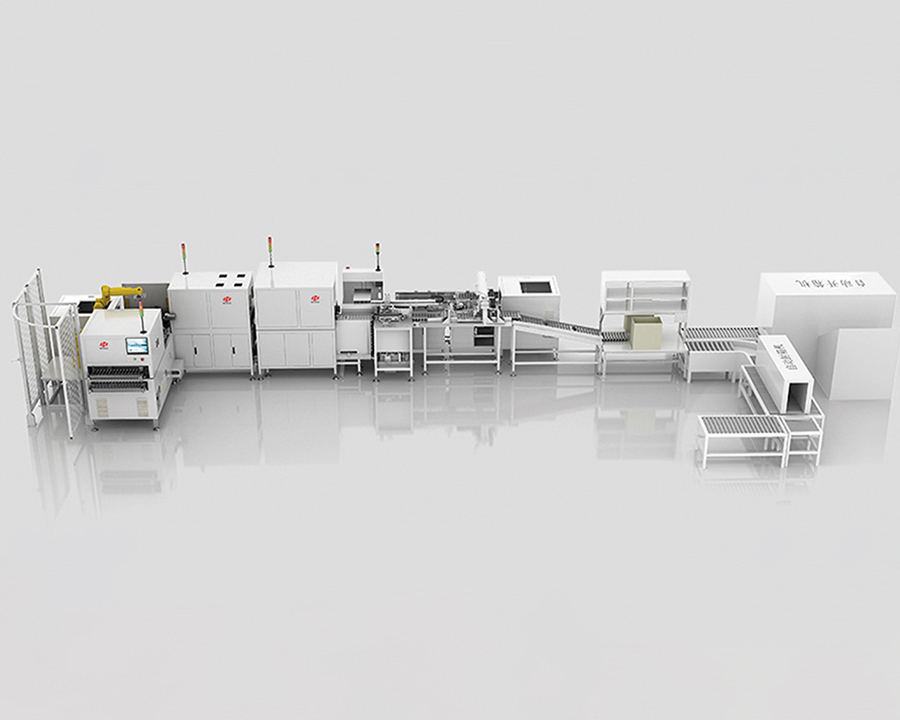

Many automatic flag-making machines feature an all-in-one design, integrating multiple functions into a single unit. This reduces the need for multiple machines and simplifies the production workflow.

The adoption of automatic flag-making machines offers several benefits to manufacturers and end-users:

Increased Efficiency:

Automation significantly reduces the time required for flag production, enabling manufacturers to produce larger quantities in shorter periods. This increased efficiency allows for quicker turnaround times and better meeting customer demands.

Cost Savings:

By automating the production process, manufacturers can reduce labor costs and minimize waste. This leads to lower overall production costs, which can be passed on to consumers in the form of more affordable flags.

Improved Quality:

Automatic flag-making machines offer consistent, high-quality prints that are difficult to achieve through manual methods. This ensures that every flag produced meets the highest standards of quality and durability.

Customization:

The ability to print in multiple colors and resolutions allows for the production of highly customized flags. This is particularly useful for organizations and individuals seeking to create unique flags that reflect their identity and values.

English

English русский

русский عربى

عربى